Design and Application of 5L Extrusion Blow Molding Machines in Mid-Volume Packaging Production Abstract

1. Introduction

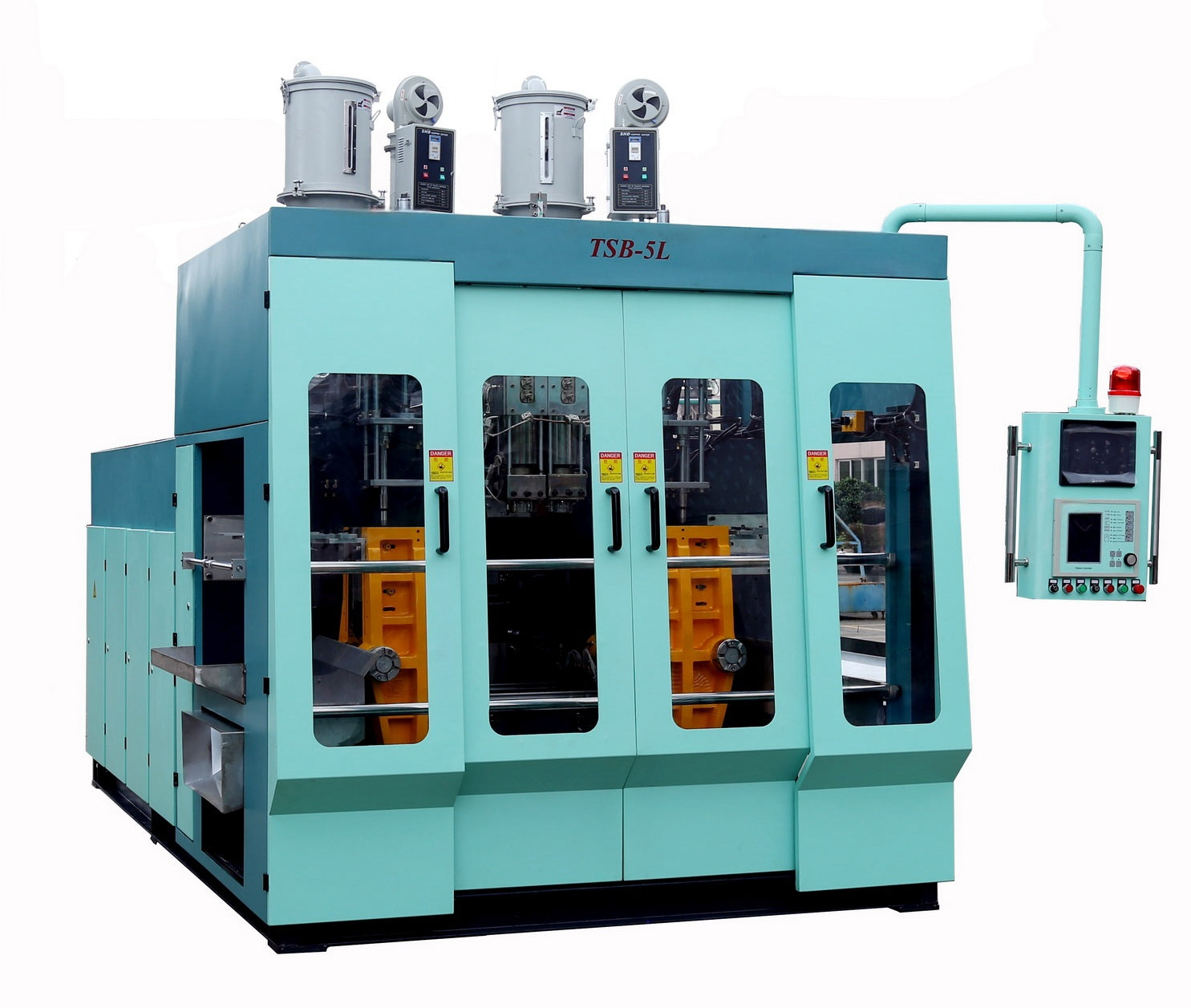

The global demand for 3–10 liter plastic containers has surged due to rising consumption of liquid detergents, edible oils, agrochemicals, and bulk beverages in emerging markets [4][6]. In this context, the 5L extrusion blow molding machine has emerged as a versatile workhorse for small-to-mid-sized plastic processors seeking to balance throughput, product quality, and capital investment.

Unlike small-volume machines (<1L) optimized for high-speed single-cavity output or large accumulator-head systems (>20L) designed for thick-walled IBC totes, the 5L class prioritizes multi-cavity capability, material versatility, and rapid reconfiguration between product formats. Recent models from Chinese OEMs—such as Dongguan Jinjun’s DKB-5L and Dongguang Jinchengxin’s XL80-10L—demonstrate significant advances in automation, energy efficiency, and wall uniformity control [4][6].

This paper examines the design principles, subsystem integration, and industrial applications of contemporary 5L EBM machines, drawing on technical specifications, patent literature, and industry reports up to 2025.

2. Machine Architecture and Core Subsystems

A typical 5L EBM machine integrates four functional modules:

2.1 Extrusion System

- Single-screw extruder with screw diameter of Φ65–80 mm and L/D ratio of 24:1–25:1 ensures stable melt delivery for HDPE at 180–220°C [6][8].

- Motor power: 15–22 kW, often equipped with variable frequency drives (VFDs) to match load requirements and reduce idle energy loss [1].

- Barrel heating zones: 3–4 segments, with total heating power of 7–12 kW [8].

2.2 Die Head and Parison Control

- Central or side-fed annular die head with streamlined, dead-end-free flow channels enables fast color changes and minimizes melt degradation [6].

- Advanced models support 1–6 layer co-extrusion, using spiral or heart-shaped mandrel designs to ensure uniform layer distribution [6].

- Parison thickness control: Modern systems employ servo motors or asynchronous actuators to dynamically adjust the mandrel-die gap during extrusion. Control points range from 20 to 128, achieving wall tolerance within ±0.05–0.1 mm [2][10].

- Optional visible fill-line inserts allow precise liquid-level marking without secondary printing—a key feature for detergent and oil bottles [6].

2.3 Mold Clamping and Actuation

- Dual-station linear guide system (e.g., U-type frame with linear rails) enables simultaneous cooling and blowing, doubling effective cycle rate [8].

- Clamping force: 80–150 kN, sufficient for 5L molds with cavity dimensions up to 400 × 300 mm [8].

- Opening stroke: 500–600 mm, accommodating tall containers with integrated handles [8].

- Some machines (e.g., DKB-5L) support 1–4 die heads with center distances adjustable from 80–180 mm, facilitating multi-cavity production [4].

2.4 Control and Energy Systems

- PLC + HMI interface supports recipe storage, multilingual operation, and real-time monitoring of temperature, pressure, and cycle time [1][8].

- Electromagnetic heating replaces traditional resistance coils, reducing thermal loss by 30–70% through direct induction and improved insulation [1].

- Hydraulic systems operate at 16 MPa, while pneumatic circuits use 0.8 MPa compressed air for blow inflation [8].

3. Process Parameters and Performance Metrics

| Parameter | Typical Range |

|---|---|

| Max. volume | 5 L (some models up to 10 L) |

| Output capacity | 3,000–60,000 pcs/24h |

| Cycle time | 8–20 seconds |

| Material | HDPE (most common), PP, PCR-PE |

| Wall thickness | 1.8–3.0 mm (programmable) |

| Screw speed | 20–67 rpm |

| Total installed power | 45–60 kW |

| Machine weight | 7,000–9,000 kg |

| Footprint | ~4.4 × 3.6 × 2.5 m |

Wall thickness consistency directly impacts drop-test performance and material usage. Studies show that uniform walls reduce resin consumption by 15–20% while improving impact resistance [2].

4. Industrial Applications

The 5L EBM machine is widely used in:

- Daily Chemicals: Laundry detergent, fabric softener, dishwashing liquid bottles (HDPE, opaque white/blue).

- Food & Beverage: Edible oil containers, vinegar jugs, syrup dispensers (food-grade HDPE/PP).

- Agriculture: Pesticide and fertilizer tanks (requiring chemical resistance and UV stabilizers).

- Industrial: Lubricant cans, cleaning solvent packs.

These products often require:

- Integrated handles,

- Tamper-evident neck finishes,

- Recycled content compliance (≥30% PCR in China/EU),

- Multi-layer structures for oxygen/moisture barrier (e.g., HDPE/EVOH/HDPE).

5. Technological Innovations and Market Trends

According to the 2025 International Chinaplas Exhibitor Data, Chinese manufacturers now dominate the 1–10L EBM segment, offering machines at 40–60% lower cost than European counterparts while meeting CE and ISO standards [4][6].

Key trends include:

- Multi-head configurations: DKB-5L supports up to four die heads, enabling 2–8 cavity output without major retooling [4].

- All-electric actuation: Emerging models replace hydraulics with servo-electric clamping, eliminating oil leakage and noise [12].

- Smart manufacturing integration: Remote diagnostics, predictive maintenance, and IoT-enabled production tracking are becoming standard [8].

- Circular economy alignment: Machines are optimized for 100% PCR feedstock, supporting brand owners’ net-zero commitments [2][12].

China’s “dual carbon” policy further accelerates adoption of energy-efficient technologies, with electromagnetic heating and VFDs now standard on >70% of new 5L machines [1].

6. Sustainability and Energy Efficiency

Modern 5L EBM machines incorporate multiple green features:

- Electromagnetic barrel heating: Saves 30–70% vs. resistive heaters by reducing heat loss and accelerating warm-up [1].

- Low-back-pressure die design: Extends gear reducer life and lowers motor load [6].

- Closed-loop water cooling: Minimizes water consumption.

- Material optimization: Precise parison control reduces flash and scrap rates to <3%.

These measures align with global ESG mandates and reduce total cost of ownership over the machine’s 10–15 year lifecycle.

7. Conclusion

The 5-liter extrusion blow molding machine exemplifies the convergence of practical engineering, digital control, and sustainable manufacturing. Through innovations in multi-layer co-extrusion, servo-driven thickness profiling, and energy-efficient heating, today’s 5L EBM systems deliver high-quality, cost-effective solutions for mid-volume packaging across diverse industries. As demand for recyclable, lightweight containers grows—and as smart factory integration deepens—this equipment class will remain a critical enabler of agile, eco-conscious plastic production worldwide.

-

Đăng trong

extrusion blow molding machine