Digital Transformation and Information Technology Integration in Industrial Chiller Systems

Abstract

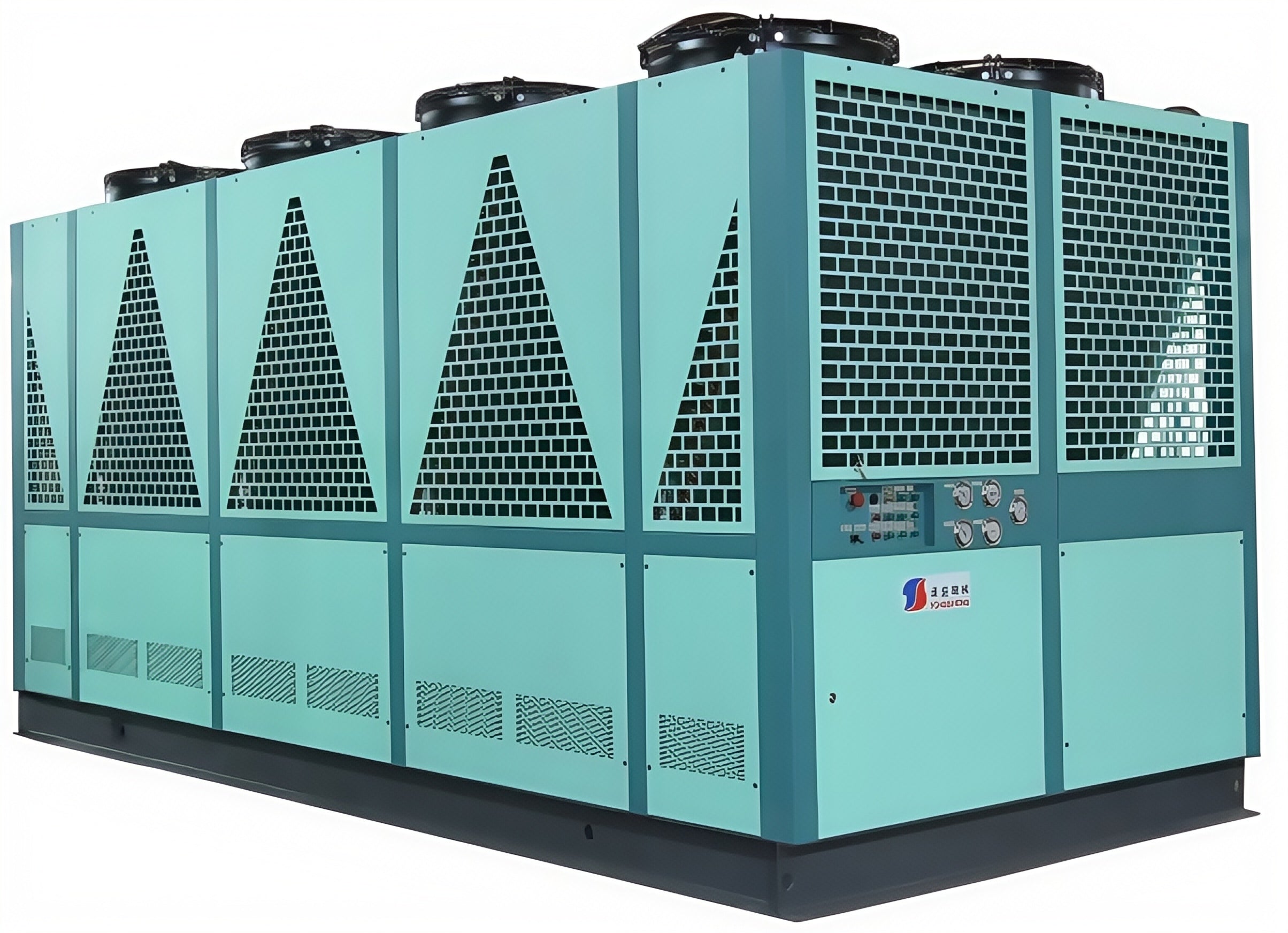

Industrial chillers play a critical role in maintaining process stability across industries such as manufacturing, data centers, and commercial buildings. With the advent of Industry 4.0, the integration of information technologies (IT) such as IoT, cloud computing, and AI into chiller systems has revolutionized their monitoring, control, and maintenance. This paper explores the current state of IT-driven innovations in industrial chillers, analyzes case studies, and discusses challenges and future trends in achieving intelligent, energy-efficient cooling solutions.

1. Introduction

Industrial chillers are essential for precision temperature control in applications ranging from aluminum anodizing to data center cooling. Traditional systems face limitations in energy efficiency, real-time monitoring, and predictive maintenance. The integration of information technology (IT) into chiller systems—termed "chiller informatics"—has emerged as a transformative approach to address these challenges. This paper reviews key technologies, implementation strategies, and benefits of信息化 (informatization) in industrial chillers.

2. Key Technologies Driving Chiller Informatization

2.1 Internet of Things (IoT) and Remote Monitoring

- Real-Time Data Acquisition: IoT-enabled sensors and PLCs (Programmable Logic Controllers) collect parameters such as water temperature, pressure, flow rate, and power consumption.

- Remote Access: Cloud platforms allow operators to monitor chiller performance via smartphones or computers, enabling proactive maintenance (e.g., 物通博联’s IoT gateway solution).

- Case Study: Suzhou Hemei’s IoT platform enables ±0.1°C temperature control and 72-hour fault prediction, reducing downtime by 40% (资料5).

2.2 Big Data Analytics and Predictive Maintenance

- Data-Driven Optimization: Historical and real-time data analysis identifies patterns to optimize energy use and predict component failures.

- Example: A cloud-based system reduced maintenance costs by 30% through anomaly detection in cooling tower performance (资料2).

2.3 Artificial Intelligence (AI) and Smart Control

- AI Algorithms: Machine learning models adjust chiller loads dynamically based on environmental conditions and demand forecasts.

- Case Application: AI-controlled magnetic levitation chillers in Shanghai commercial complexes achieved a 35% energy efficiency improvement (资料5).

2.4 Cloud Computing and Centralized Management

- Scalable Infrastructure: Cloud platforms aggregate data from multiple chillers for centralized management, enabling energy audits and cross-system optimization.

- Example: A DCS (Distributed Control System) for HVAC systems reduced labor costs by 50% through automated reporting and diagnostics (资料9).

3. Implementation Strategies

3.1 Retrofitting Legacy Systems

- Low-Cost Upgrades: Integrating PLCs with existing chillers (e.g., 凯德利’s retrofit方案) enables remote monitoring without replacing entire systems.

- Benefits: Achieved 10% energy savings in aging office building chillers through automated load balancing (资料4).

3.2 Smart Factory Integration

- IIoT (Industrial IoT) Ecosystem: Chillers communicate with MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) for end-to-end process optimization.

- Example: A modular "zero-carbon cold station" in China reduced installation time by 20% via prefabricated IoT-enabled chillers (资料5).

4. Challenges and Mitigation Strategies

4.1 Technical Challenges

- Data Security: Vulnerabilities in IoT devices and cloud platforms require robust encryption and firewall protocols.

- Interoperability: Standardizing communication protocols (e.g., Modbus, BACnet) ensures seamless integration with legacy systems (资料9).

4.2 Economic and Operational Barriers

- High Initial Costs: Government subsidies and phased implementation can offset upfront investments.

- Skill Gaps: Training programs for technicians in IoT, AI, and cloud technologies are critical (资料1).

5. Future Trends

- Zero-Carbon Chillers: Integration with renewable energy sources (e.g., solar PV) and refrigerants with low global warming potential (GWP).

- Edge Computing: Decentralized data processing at the chiller site to reduce latency and improve real-time decision-making.

- Digital Twins: Virtual replicas of physical chillers for simulation, testing, and predictive maintenance (资料8).

6. Conclusion

The informatization of industrial chillers represents a paradigm shift from reactive to proactive maintenance, energy efficiency optimization, and smart factory integration. By leveraging IoT, AI, and cloud computing, industries can achieve significant cost savings, sustainability, and operational resilience. However, overcoming technical and economic barriers requires collaborative efforts among policymakers, manufacturers, and academia. As demonstrated by case studies, the future of industrial chilling lies in the seamless fusion of mechanical engineering and information technology.