Design, Intelligence, and Sustainable Application of Air-Cooled Screw Chillers in Modern Industrial and Commercial HVAC Systems Abstract

1. Introduction

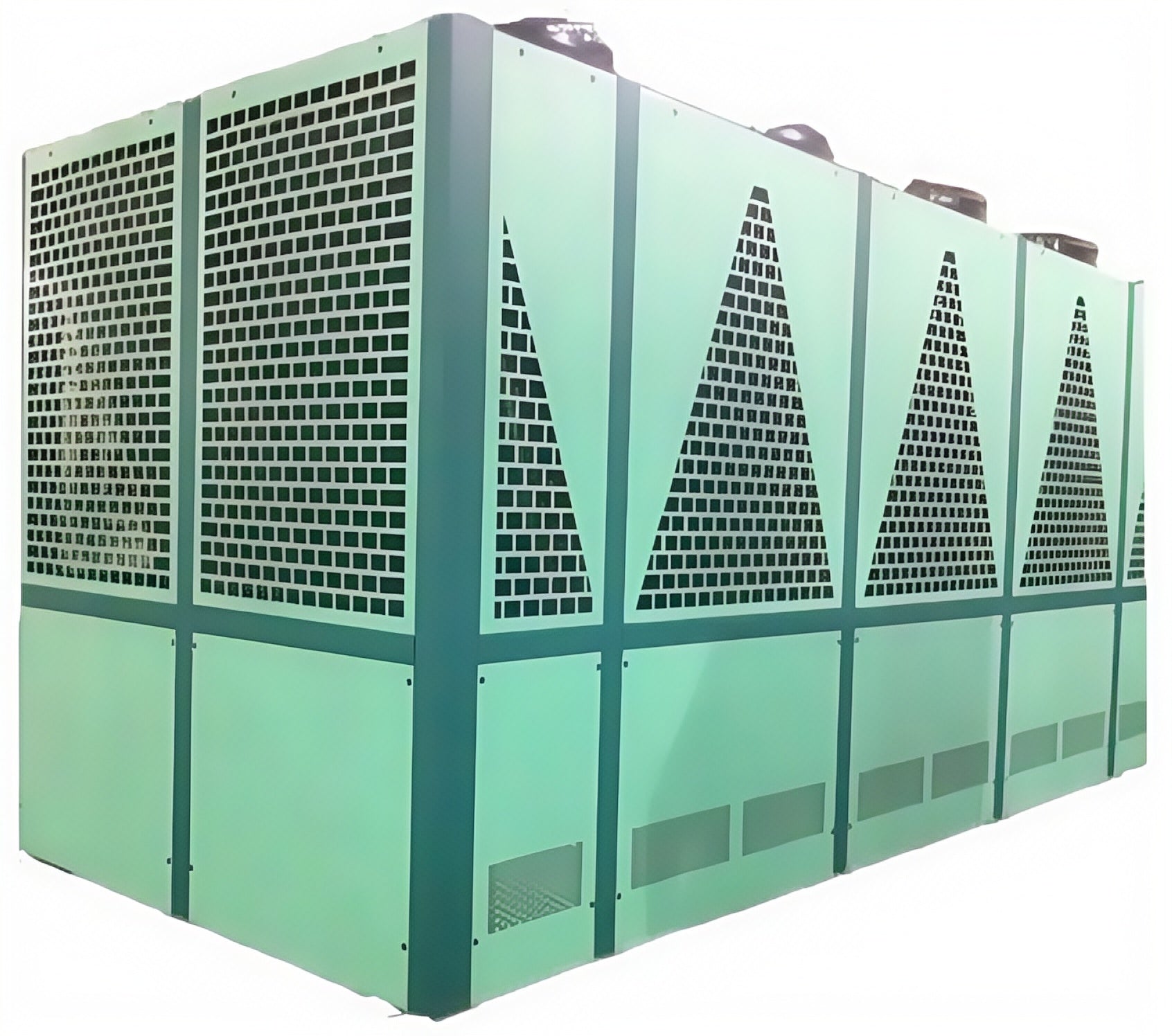

As urbanization accelerates and climate resilience becomes paramount, efficient, water-free cooling technologies are gaining strategic importance. The air-cooled screw chiller—which rejects heat directly to ambient air via finned-tube condensers—offers a compelling alternative to water-cooled systems, especially in regions facing water scarcity, high water treatment costs, or limited installation space [7][9].

Unlike centralized chilled water plants requiring cooling towers, pumps, and extensive piping, air-cooled units are self-contained, factory-assembled, and require only electrical and chilled water connections. This “plug-and-play” advantage has driven an 8.5% annual growth in China’s industrial refrigeration market, where air-cooled screw chillers now account for 32% of new installations in sectors like food processing, pharmaceuticals, and data centers [1][7].

This paper examines the technological evolution, performance characteristics, and real-world deployment of contemporary air-cooled screw chillers, with emphasis on reliability, adaptability, and sustainability.

2. System Architecture and Working Principle

An air-cooled screw chiller operates on the vapor-compression refrigeration cycle, comprising four core components:

- Twin-screw compressor: Compresses low-pressure refrigerant vapor into high-pressure gas.

- Air-cooled condenser: Rejects heat to ambient air via axial fans and finned copper-aluminum coils.

- Expansion device: Typically a thermostatic expansion valve (TXV) or electronic metering device.

- Shell-and-tube or brazed-plate evaporator: Absorbs heat from chilled water (typically 7°C outlet).

The entire system is housed in a single skid-mounted unit, eliminating the need for external cooling towers [4][5].

Modern units integrate PLC-based controllers (e.g., Siemens or Hollysys LM series) that monitor:

- Suction/discharge pressures,

- Chilled water inlet/outlet temperatures,

- Compressor oil level and temperature,

- Fan motor status.

Safety features include high-pressure cutouts, phase loss protection, anti-freeze logic, and fault self-diagnosis [5][7].

3. Core Technological Advancements

3.1 High-Efficiency Twin-Screw Compressor

Most units employ 5:6 asymmetric rotor profiles, achieving volumetric efficiency >92% and reducing internal leakage [1][4]. For example, Nuoleng’s air-cooled models use international-brand semi-hermetic compressors optimized specifically for air-cooled duty cycles, delivering 8% higher efficiency than standard screw designs [1][7].

Capacity is modulated via:

- Four-stage stepped control (100%–75%–50%–25%), or

- Continuous (stepless) modulation using a sliding valve combined with Inlet Guide Vanes (IGV) and VFDs, enabling smooth operation from 10% to 100% load [4][8].

3.2 Advanced Heat Exchanger Design

Condensers typically feature copper tubes with hydrophilic aluminum fins, offering 12% higher heat transfer efficiency and resistance to corrosion and frost buildup in humid or coastal environments [1][7].

Evaporators are either:

- Shell-and-tube (for high-pressure industrial applications, rated up to 2.5 MPa), or

- Brazed-plate (compact, efficient, but limited to ≤1.6 MPa)—as used in YORK’s compact models [7].

3.3 Intelligent Control and Remote Monitoring

Units from leading brands (e.g., Nuoleng, Carrier) now support:

- Modbus/Profibus communication for integration with BMS or MES systems,

- Touchscreen HMI with bilingual (Chinese/English) interfaces,

- Remote parameter adjustment and fault alerts via cloud platforms [1][5].

Notably, Nuoleng’s PLC system includes a “first-out cause memory” function, helping engineers pinpoint the root cause of shutdowns within seconds—reducing downtime by up to 40% [5].

4. Energy Performance and Environmental Impact

While air-cooled chillers inherently operate at higher condensing temperatures than water-cooled counterparts, recent advances have narrowed the efficiency gap:

| Metric | Typical Value (2025) | Industry Average |

|---|---|---|

| EER (Energy Efficiency Ratio) | 3.6–3.8 | ~3.3 |

| IPLV (Integrated Part Load Value) | 4.0–4.5 | ~3.7 |

A Nuoleng 500 kW unit achieved EER = 3.8 using VFD + IGV hybrid control, translating to 15% lower annual energy use vs. fixed-speed competitors [7].

On refrigerants, most units remain compatible with R134a (GWP = 1,430), but next-gen models are adopting R513A (GWP = 573) and R1234ze (GWP < 1), aligning with China’s updated environmental regulations and the Kigali Amendment [3][10].

5. Real-World Applications

5.1 Food & Beverage Industry

A frozen food plant in Jiangsu installed a Nuoleng -18°C air-cooled screw chiller with humidity-resistant coating and enhanced defrost logic. The system maintained stable cooling in 90% RH environments, reducing frost-related maintenance by 60% and saving ¥240,000/year in electricity [7].

5.2 Commercial HVAC

Large shopping malls in Guangzhou deploy modular air-cooled chillers on rooftops, avoiding basement mechanical rooms. Units with noise levels <72 dB(A) meet urban acoustic standards while delivering 100% redundancy [9].

5.3 Infrastructure Projects

At Taiyuan Wusu International Airport, Obo Air-Cooled Screw Chillers provided rapid cooling during peak passenger flow, achieving setpoint temperature within 8 minutes—critical for passenger comfort in transit hubs [2].

6. Maintenance and Reliability

Key maintenance practices include:

- Quarterly coil cleaning to prevent airflow blockage (fouling can reduce EER by 15%),

- Annual oil/filter replacement,

- Vibration monitoring—bearing clearance >0.15 mm increases power consumption by 9% [4].

Predictive maintenance via IoT sensors enables early detection of fan imbalance, refrigerant leaks, or compressor wear—extending service life beyond 15 years [8].

7. Market Trends and Future Outlook

China’s air-cooled screw chiller market is projected to grow at 12% CAGR, reaching RMB 20 billion by 2030 [9]. Drivers include:

- Water conservation policies in northern China,

- Rapid urbanization in Tier-2/3 cities,

- Demand for modular, scalable cooling in data centers and EV battery plants.

Future innovations will focus on:

- AI-driven load forecasting for optimal chiller sequencing,

- Hybrid solar-assisted pre-cooling,

- Digital twins for real-time performance simulation,

- Standardized IoT protocols (e.g., BACnet over MQTT) for seamless building integration.

8. Conclusion

The air-cooled screw chiller is no longer a “compromise” for water-limited sites—it is a strategic, intelligent, and sustainable cooling platform. By combining robust mechanical design, smart controls, and eco-friendly refrigerants, it delivers reliable performance across diverse climates and industries. As the world balances energy, water, and carbon constraints, this technology will play an increasingly central role in shaping resilient and efficient thermal infrastructure.

-

Posted in

Industrial chiller