Design, Applications, and Market Trends of Material Shredders Abstract

1. Introduction

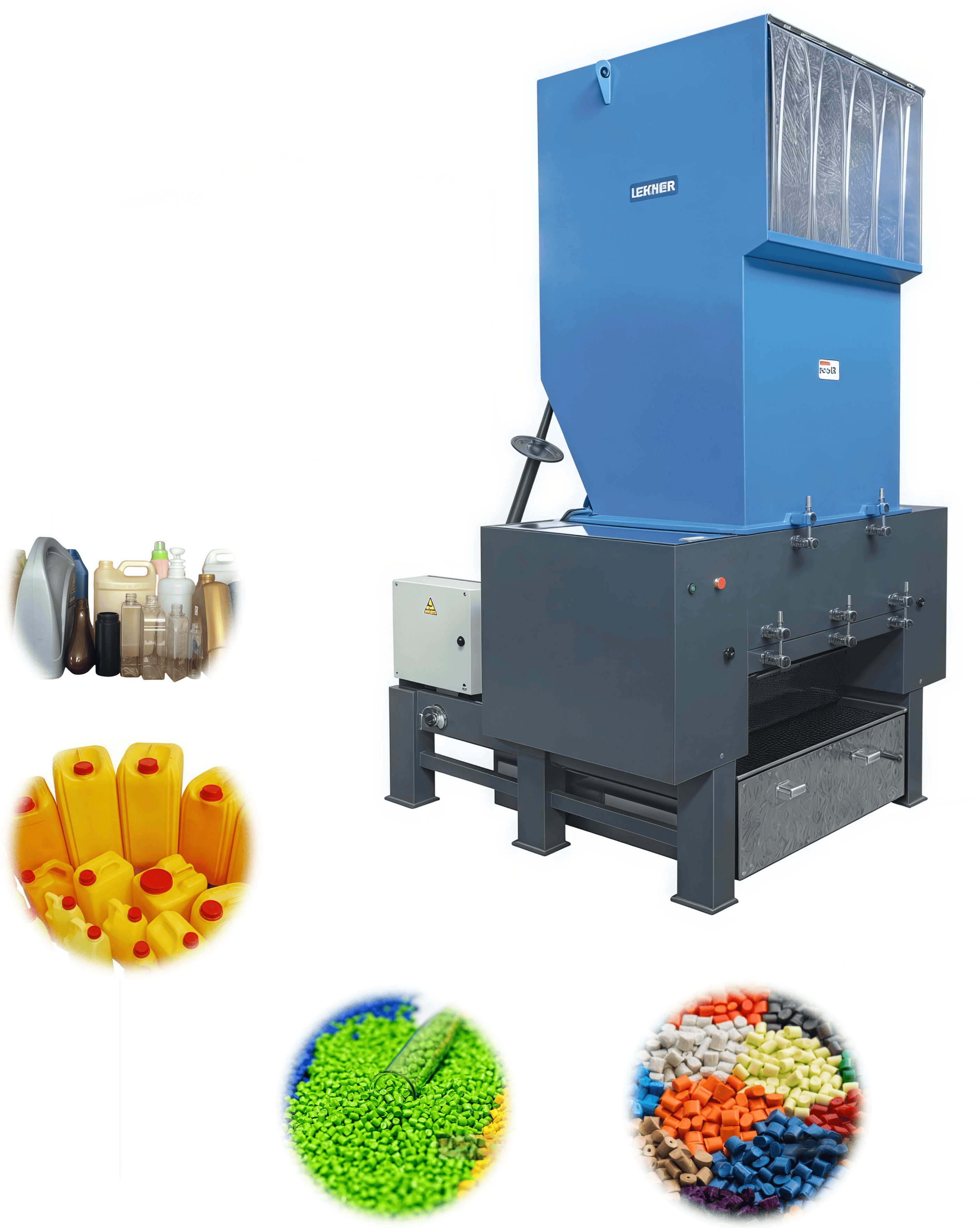

Material shredders are mechanical devices designed to reduce the size of solid materials through cutting, tearing, or crushing. They are widely used in recycling (e.g., plastics, metals), agriculture (e.g., feed processing), and industrial manufacturing (e.g., mineral processing). This paper explores the evolution of shredder technology, emphasizing their adaptability to diverse materials and industries.

2. Technical Design and Specifications

2.1 Core Components

Shredders typically consist of:

- Cutting System: Rotating knives or hammers (e.g., rectangular hammers for feed shredders) and fixed blades.

- Motor and Drive: Power ranges from 7.5 kW (small feed shredders) to 315 kW (industrial-grade machines).

- Screening Mechanism: Adjustable sieve gaps (4–20 mm) to control output particle size.

- Safety Features: Overload protection, vibration dampening, and noise reduction systems.

2.2 Performance Metrics

| Model | Input Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|---|

| Efficient Fine Crusher 800×800 | <180 | <5 | 45–65 | 45–55 |

| Hammer Shredder | <300 | <40 | 180 | 1000 |

| Plastic Granulator | - | - | 200–250 | 250 |

2.3 Energy Efficiency

Modern shredders integrate energy-saving technologies:

- Variable-Frequency Drives (VFDs): Reduce power consumption by 15–30%.

- High-Strength Materials: Hammer blades made of 65Mn steel or tungsten carbide coatings extend lifespan.

- Optimized Airflow: Dust suppression systems in agricultural shredders minimize environmental impact.

3. Industrial Applications

3.1 Recycling Industry

- Plastic Shredders: Process waste PET, HDPE, and PVC into granules for remanufacturing. China’s plastic shredder market grew at 10% CAGR (2024), driven by policy bans on single-use plastics (Knowledge Base [4]).

- Metal and E-Waste: Shred cables, PCBs, and appliances for metal recovery.

3.2 Agriculture

-

Feed Shredders: Convert corn stalks, straw, and hay into 3–5 mm particles for livestock feed.

- Design Example: A modular hammer shredder with a 7.5–11 kW motor achieves 500–800 kg/h throughput (Knowledge Base [10]).

3.3 Mining and Construction

- Cone Crushers: Process medium-hardness ores (e.g., limestone) with capacities up to 1,000 t/h (Knowledge Base [12]).

- Impact Crushers: Handle brittle materials like gypsum and coal, achieving <5 mm output (Knowledge Base [9]).

3.4 Medical and Sanitary Products

- Sterile Shredders: Destroy confidential documents and medical waste while complying with ISO 14001 standards.

4. Market Trends and Competitive Landscape

4.1 Global Demand Drivers

- Circular Economy: EU and China’s plastic recycling policies boost shredder demand.

- Urbanization: Construction waste recycling drives adoption of mobile shredders.

- Automation: IoT-enabled shredders with real-time monitoring reduce downtime by 30% (Knowledge Base [4]).

4.2 Regional Market Dynamics

- Asia-Pacific: China dominates with 47.8% of global rubber shredder capacity (Knowledge Base [11]).

- Europe: Focus on low-emission, high-efficiency models per EU Ecodesign regulations.

4.3 Key Players

- Sandvik (Sweden): Innovated the Flexifeed system for cone crushers, extending wear part lifespan by 50% (Knowledge Base [1]).

- Zhangjiagang Longsi Machinery (China): Leads in low-cost, high-volume plastic shredders.

5. Future Innovations

5.1 Industry 4.0 Integration

- AI-Powered Optimization: Predictive maintenance using vibration and temperature sensors.

- Robotics: Automated feeding and sorting systems for mixed-waste processing.

5.2 Sustainability Advances

- Biodegradable Materials: Shredders compatible with PLA and PHA plastics.

- Carbon Footprint Reduction: Hybrid electric-hydraulic systems cut energy use by 40%.

5.3 Modular and Mobile Solutions

- Portable Shredders: Truck-mounted units for on-site construction waste processing.

6. Conclusion

Material shredders are indispensable in modern manufacturing and recycling. Their technical evolution—from energy-efficient motors to AI-driven automation—positions them as key enablers of sustainability. As global demand for resource recovery grows, further innovations in modular design and eco-friendly technologies will be critical to maintaining competitiveness in the $100+ billion global market.