Design, Applications, and Market Trends of Chiller Systems Abstract

1. Introduction

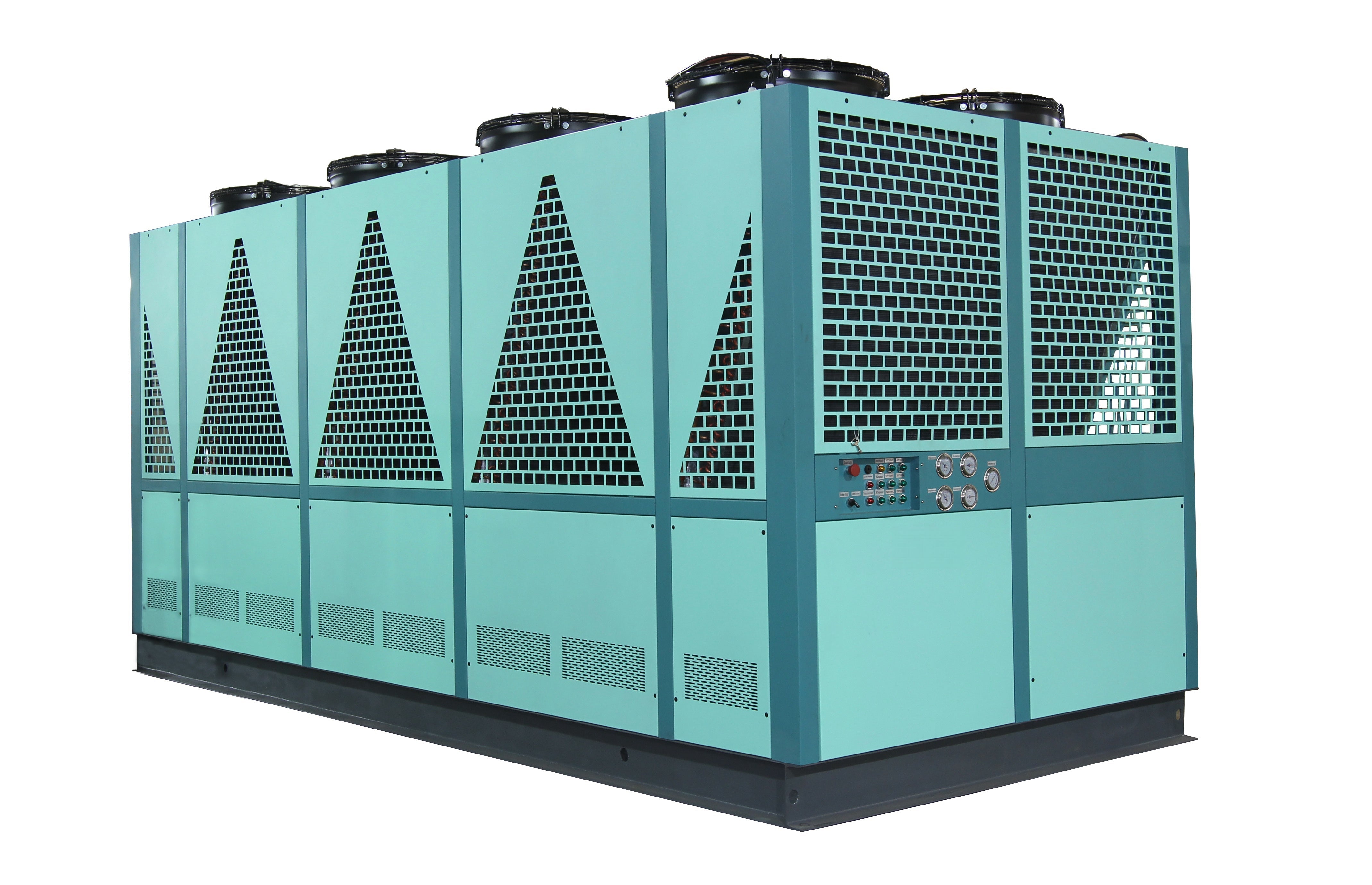

Chiller systems utilize vapor-compression or absorption cycles to remove heat from fluids, enabling temperature regulation in diverse settings. They are integral to industries such as chemical processing, pharmaceuticals, food manufacturing, and data centers. This paper explores the evolution of chiller technology, emphasizing their adaptability to modern energy and environmental challenges.

2. Technical Design and Principles

2.1 Core Components

Chillers consist of four primary components:

- Compressor: The "heart" of the system, compressing refrigerant vapor (e.g., R-134a or R-22) into high-temperature, high-pressure gas.

- Condenser: Dissipates heat via air-cooled or water-cooled methods, condensing refrigerant into liquid.

- Expansion Valve: Reduces refrigerant pressure, creating a low-pressure, low-temperature mixture.

- Evaporator: Absorbs heat from the target fluid (e.g., water), causing refrigerant to evaporate and complete the cycle.

2.2 Refrigeration Cycle

| Stage | Process | Temperature Change | Function |

|---|---|---|---|

| Compression | Low-pressure vapor → High-pressure gas | ↑ | Increases refrigerant energy |

| Condensation | High-pressure gas → High-pressure liquid | ↓ | Heat dissipation to environment |

| Expansion | High-pressure liquid → Low-pressure mixture | ↓ | Temperature drop for evaporation |

| Evaporation | Liquid-vapor mixture → Vapor | ↑ | Heat absorption from target fluid |

2.3 Energy Efficiency Metrics

Modern chillers prioritize energy efficiency through technologies such as:

- Variable Speed Drives (VSDs): Reduce energy consumption by 30–40% in centrifugal chillers.

- Magnetic Bearings: Eliminate mechanical friction (e.g., Hanbell’s magnetic levitation compressors).

- Smart Control Systems: AI-driven load prediction and IoT-based monitoring (e.g., Johnson Controls’ MetaSys® platform).

3. Industrial Applications

3.1 Chemical and Pharmaceutical Industries

- Chemical Reactors: Maintain precise temperatures for exothermic/endothermic reactions (e.g., organic synthesis at ±0.1°C accuracy).

- Pharmaceutical Storage: Ensure stable low-temperature environments for drug preservation.

3.2 Food and Beverage Processing

- Cold Storage: Preserve perishables like dairy and meat at 0–4°C.

- Production Lines: Rapid cooling of baked goods and beverages to meet hygiene standards.

3.3 Semiconductor Manufacturing

- Precision Cooling: ±0.1°C control for wafer etching and photolithography processes.

- Data Centers: Maintain server room temperatures below 27°C to prevent overheating.

3.4 Commercial HVAC Systems

- Building Air Conditioning: Centrifugal chillers (e.g., York and Carrier models) dominate large-scale projects, achieving COP values up to 6.5.

4. Market Trends and Competitive Landscape

4.1 Global Demand Drivers

- Energy Efficiency Regulations: China’s GB19577-2024 standard mandates APF ≥ 5.0 for new units.

- Green Building Initiatives: LEED certification drives adoption of magnetic levitation and natural refrigerants.

- Industrial Automation: IoT integration for predictive maintenance and real-time monitoring.

4.2 Regional Market Dynamics

- Asia-Pacific: China’s chiller market reached ¥38 billion (≈$5.3 billion) in 2025, driven by data centers and green buildings.

- North America: Retrofitting aging infrastructure with variable-flow systems (e.g., Trane’s dual-screw compressors).

4.3 Key Players

-

International Brands:

- Carrier: Semi-hermetic compressors with IPLV ≥ 9.5 for skyscrapers.

- Trane: Dual-screw compressors for cold-chain logistics (-20°C operation).

-

Domestic Brands:

- Gree: Dual-stage permanent magnet VSD screw chillers (COP 7.17 in metro projects).

- Midea: AI-optimized water-cooled units (40% partial-load efficiency gain).

5. Future Innovations

5.1 Industry 4.0 Integration

- AI-Powered Optimization: Predictive maintenance using vibration and temperature sensors.

- Digital Twins: Simulate chiller performance for real-time efficiency adjustments.

5.2 Sustainability Advances

- Natural Refrigerants: CO₂ and ammonia-based systems reduce GWP (Global Warming Potential).

- Waste Heat Recovery: Integrate heat exchangers to repurpose waste energy for district heating.

5.3 Modular and Hybrid Solutions

- Hybrid Chillers: Combine VSD compressors with free-cooling modules (e.g., DunAn’s winter natural cooling systems).

6. Conclusion

Chiller systems are indispensable in modern industry and infrastructure. Their technical evolution—from magnetic bearings to AI-driven controls—positions them as key enablers of energy efficiency and sustainability. As global demand for green technologies grows, innovations in modular design and eco-friendly refrigerants will be critical to maintaining competitiveness in the $50+ billion global market.