The Current Status and Future of Hollow Plastic Products(B)

3. Environmental Impact of Hollow Plastic Products 3.1 Accumulation of Plastic Waste The accumulation of plastic waste is a pressing issue. Millions of tons of plastic waste enter oceans annually, forming massive garbage patches that harm marine life. Microplastics, resulting from the breakdown of larger plastic pieces, enter the food chain, posing risks to human health. 3.2 Production and Disposal The production of hollow plastic products contributes to resource depletion...

The Current Status and Future of Hollow Plastic Products(A)

Abstract: Hollow plastic products have become ubiquitous in various industries due to their lightweight, durable, and cost-effective nature. However, environmental concerns regarding plastic waste and pollution have necessitated a reevaluation of their production and disposal methods. This paper delves into the current status of hollow plastic products, addressing their benefits, environmental challenges, and future trends towards sustainability. 1. Introduction Hollow plastic products, characterized by their hollow structures, are widely used...

Advancements and Challenges in Pharmaceutical Plastic Packaging(B)

3. Challenges in Pharmaceutical Plastic Packaging 3.1 Compatibility Issues Ensuring the compatibility of plastic packaging materials with drug formulations is a significant challenge. Extracts and migrants from packaging can interact with active pharmaceutical ingredients (APIs), leading to degradation or altered efficacy. Rigorous testing protocols and the development of low-extractable, high-barrier materials are essential to address this concern. 3.2 Regulatory Compliance The pharmaceutical industry is subject to stringent regulations concerning packaging...

Advancements and Challenges in Pharmaceutical Plastic Packaging

Abstract: Pharmaceutical plastic packaging plays a crucial role in ensuring the stability, safety, and efficacy of medicinal products. This paper delves into the advancements in plastic packaging materials, technologies, and designs that cater to the evolving needs of the pharmaceutical industry. It also discusses the challenges faced in ensuring the compatibility, sustainability, and regulatory compliance of these packaging solutions. By analyzing current trends and future prospects, this study aims to...

Advantages of Plastic Packaging in Cosmetics and Beauty Products

Plastic packaging offers several advantages that make it a popular choice in the cosmetics and beauty industry: 2.1 Durability and Protection Plastic packaging provides excellent protection for cosmetics and beauty products, preventing contamination and prolonging shelf life. It is resistant to moisture, oxygen, and other environmental factors that can degrade product quality. 2.2 Cost-Effectiveness Plastic packaging is relatively inexpensive to produce, which helps keep the cost of cosmetics and beauty...

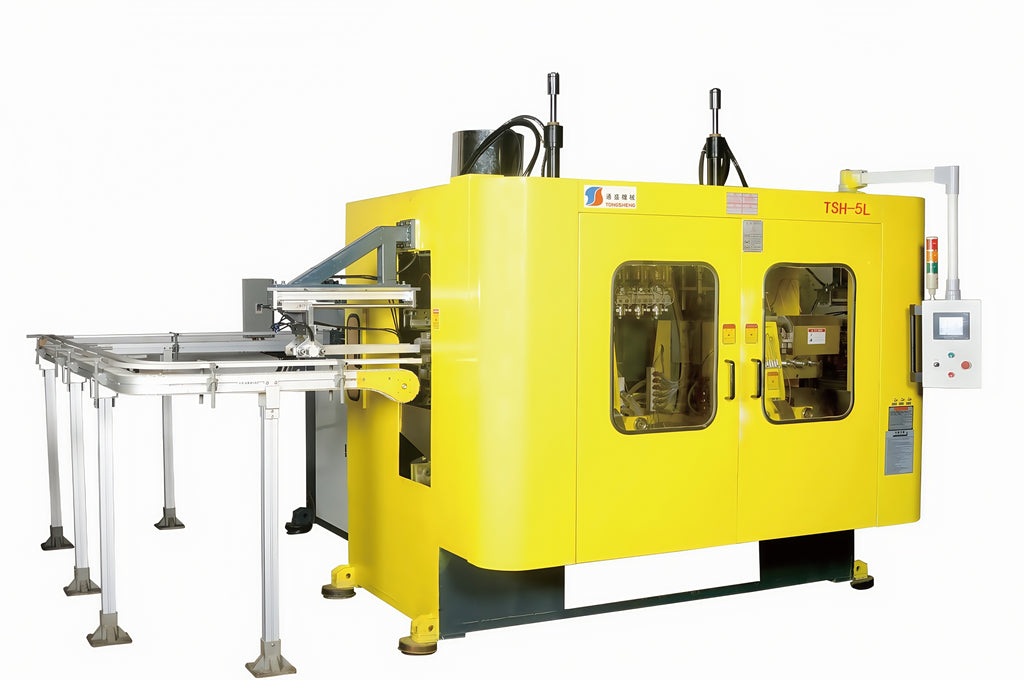

The Current State and Future Prospects of the Blow Molding Industry(B)

3. Market Trends and Drivers3.1 Growing Demand for Sustainable SolutionsConsumer awareness about the environmental impact of plastic waste has led to a surge in demand for sustainable packaging solutions. This trend is driving manufacturers to invest in research and development for biodegradable and recyclable plastics.3.2 Automation and DigitalizationThe integration of automation and digital technologies is transforming the blow molding industry. Automated systems improve production efficiency, reduce labor costs, and enable...

The Current State and Future Prospects of the Blow Molding Industry(A)

Abstract: This paper delves into the blow molding industry, examining its current state, technological advancements, market trends, environmental challenges, and future prospects. By analyzing key industry developments and market dynamics, this study aims to provide insights into the evolving landscape of blow molding and its potential for sustainable growth.1. IntroductionBlow molding is a widely used plastic processing technique that involves inflating a molten plastic tube or preform into a mold...

Heat Dissipation in Food Manufacturing and Processing Industries

3. Methods of Heat Dissipation3.1 Ventilation and Exhaust FansProper ventilation and the installation of exhaust fans are crucial for heat dissipation in food manufacturing facilities. These systems ensure the circulation of air, expelling hot air and introducing fresh air into the workspace. The strategic placement of ventilation ports and exhaust fans can significantly enhance the effectiveness of this method.3.2 Industrial Cooling SystemsIndustrial cooling systems, such as high-performance air conditioning units...