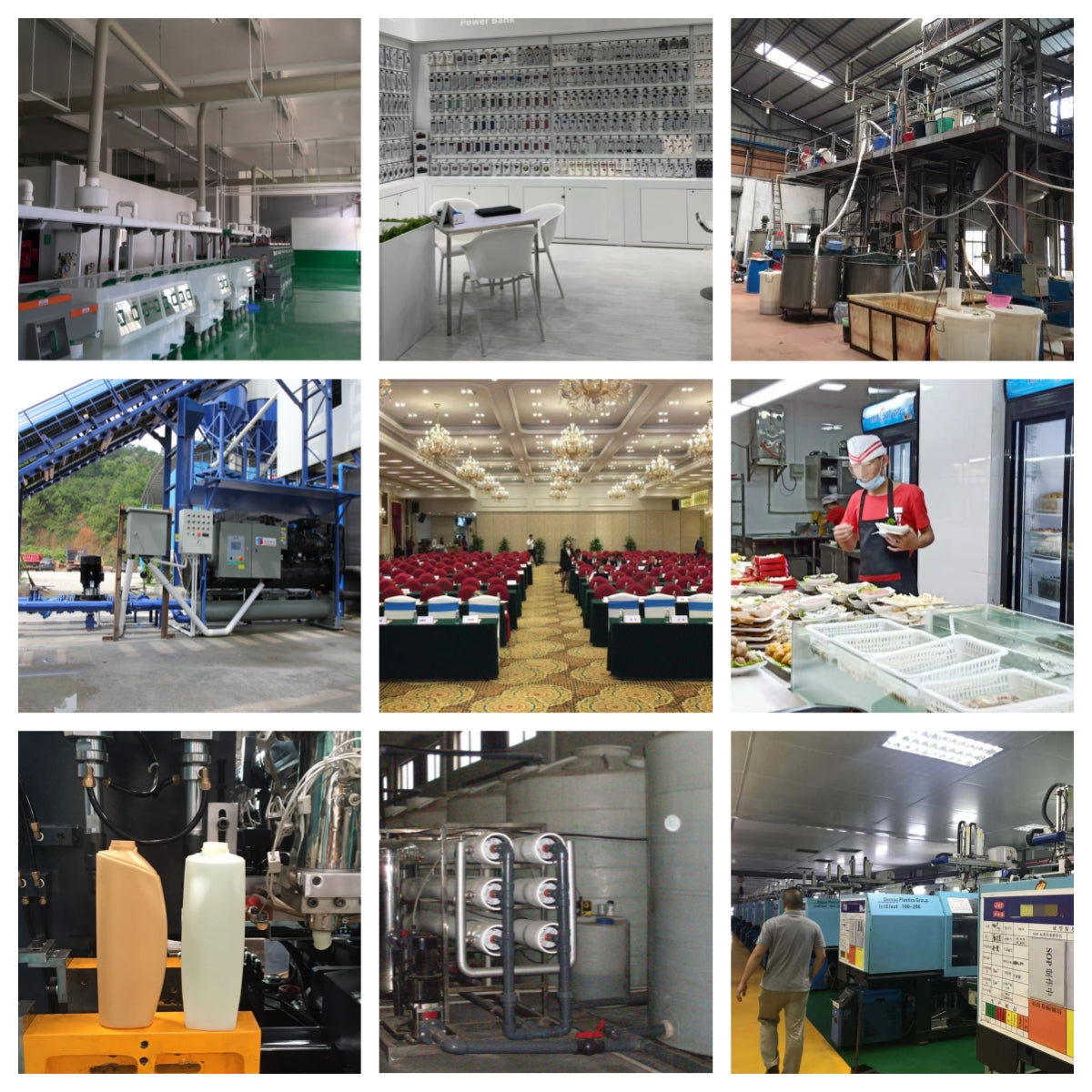

Heat Dissipation in Food Manufacturing and Processing Industries

3. Methods of Heat Dissipation

3.1 Ventilation and Exhaust Fans

Proper ventilation and the installation of exhaust fans are crucial for heat dissipation in food manufacturing facilities. These systems ensure the circulation of air, expelling hot air and introducing fresh air into the workspace. The strategic placement of ventilation ports and exhaust fans can significantly enhance the effectiveness of this method.

3.2 Industrial Cooling Systems

Industrial cooling systems, such as high-performance air conditioning units and rapid cooling machines, are commonly used in food manufacturing. Air conditioning systems maintain optimal temperature and humidity levels, crucial for certain food processes. Rapid cooling machines, on the other hand, quickly reduce the temperature of food products after processing, ensuring their freshness and extending shelf life.

3.3 Heat-Resistant Materials

The use of heat-resistant materials in the construction of food manufacturing facilities helps minimize heat transfer to the workspace. Materials with good thermal insulation properties, such as certain types of insulation foam and reflective surfaces, are often used to cover walls, roofs, and equipment.

3.4 Advanced Cooling Technologies

Emerging technologies like vacuum cooling and cryogenic freezing offer rapid and efficient heat removal. Vacuum cooling, for instance, rapidly evaporates moisture from food products under reduced pressure, achieving rapid cooling without significantly affecting the product's texture or flavor.

3.1 Ventilation and Exhaust Fans

Proper ventilation and the installation of exhaust fans are crucial for heat dissipation in food manufacturing facilities. These systems ensure the circulation of air, expelling hot air and introducing fresh air into the workspace. The strategic placement of ventilation ports and exhaust fans can significantly enhance the effectiveness of this method.

3.2 Industrial Cooling Systems

Industrial cooling systems, such as high-performance air conditioning units and rapid cooling machines, are commonly used in food manufacturing. Air conditioning systems maintain optimal temperature and humidity levels, crucial for certain food processes. Rapid cooling machines, on the other hand, quickly reduce the temperature of food products after processing, ensuring their freshness and extending shelf life.

3.3 Heat-Resistant Materials

The use of heat-resistant materials in the construction of food manufacturing facilities helps minimize heat transfer to the workspace. Materials with good thermal insulation properties, such as certain types of insulation foam and reflective surfaces, are often used to cover walls, roofs, and equipment.

3.4 Advanced Cooling Technologies

Emerging technologies like vacuum cooling and cryogenic freezing offer rapid and efficient heat removal. Vacuum cooling, for instance, rapidly evaporates moisture from food products under reduced pressure, achieving rapid cooling without significantly affecting the product's texture or flavor.