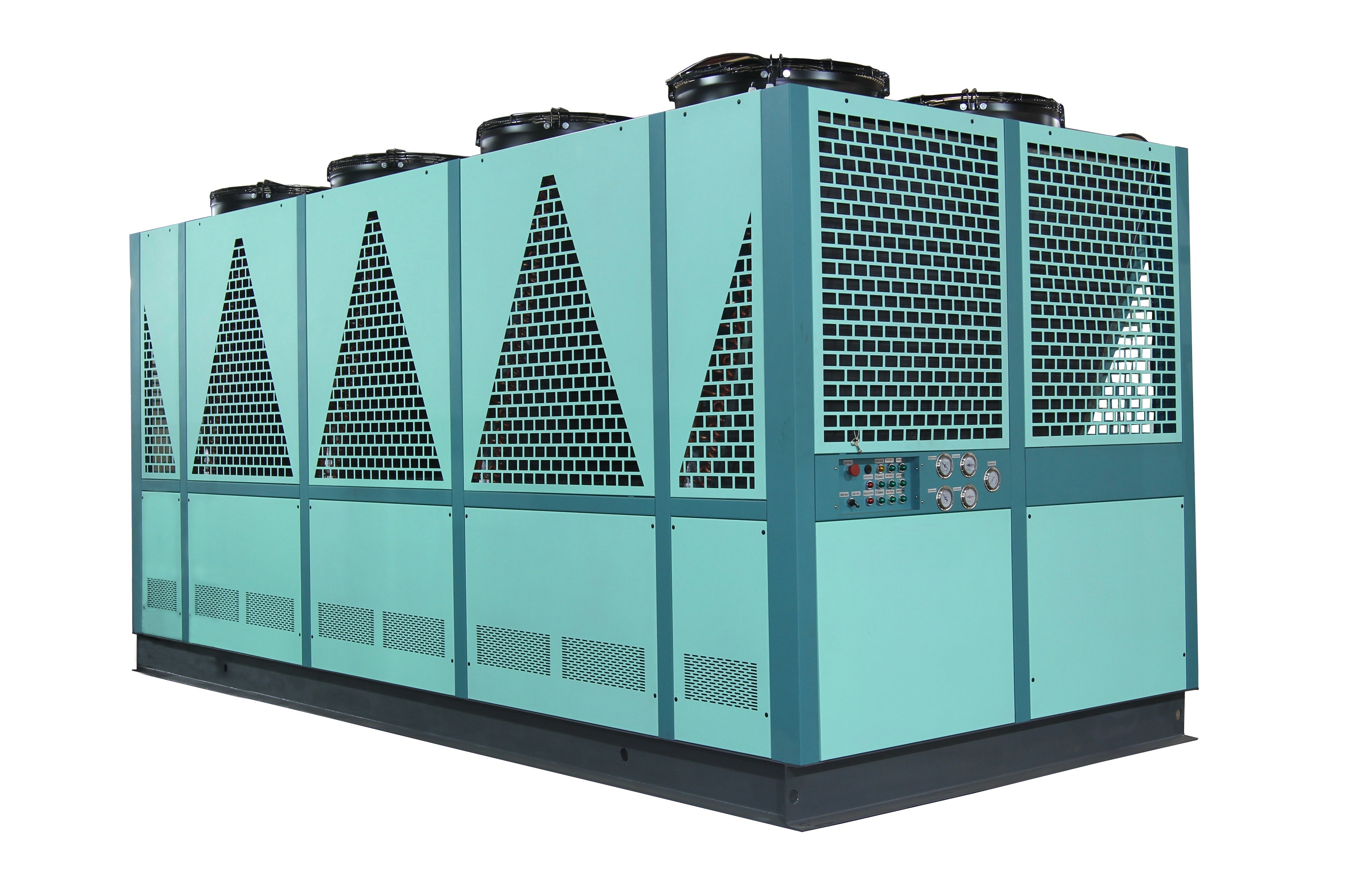

Screw Air-Cooled Chiller: Technical Analysis, Applications, and Energy Optimization

1. Introduction

Air-cooled chillers are critical in maintaining thermal comfort and industrial process efficiency. Among them, screw air-cooled chillers (SACs) stand out for their scalability, reliability, and suitability for medium-to-large cooling demands. This paper focuses on:

- The technical principles of screw compressors and air-cooled condensers.

- Applications in industries such as manufacturing, food processing, and HVAC systems.

- Energy-saving strategies validated by simulation tools like EnergyPlus (Chowdhury et al., 2009).

2. Technical Principles of Screw Air-Cooled Chillers

2.1 Core Components

-

Screw Compressor:

- Utilizes twin helical rotors to compress refrigerant, ensuring continuous and stable operation.

- Advantages: High efficiency (up to 95%), low vibration, and long service life.

-

Air-Cooled Condenser:

- Rejects heat to the ambient air via finned coils and fans.

- Eliminates water consumption, reducing operational complexity.

-

Evaporator:

- Transfers heat from the chilled water/glycol solution to the refrigerant.

-

Expansion Valve:

- Regulates refrigerant flow and pressure reduction.

2.2 Working Cycle

The refrigeration cycle follows four stages:

- Compression: Screw compressor raises refrigerant pressure.

- Condensation: Heat is dissipated via air-cooled condenser.

- Expansion: Pressure drop in the expansion valve.

- Evaporation: Refrigerant absorbs heat from the process water.

3. Applications in Industrial Facilities

3.1 Key Industries

- Manufacturing: Cooling injection molding machines, CNC equipment.

- Food Processing: Maintaining low temperatures for storage and production.

- Pharmaceuticals: Precision temperature control for drug production.

- HVAC Systems: Commercial building cooling (e.g., offices, shopping malls).

3.2 Case Study: Industrial Cooling in Australia

A study by Chowdhury et al. (2009) analyzed an SAC system in a commercial building in Rockhampton, Australia:

- Energy Consumption: Baseline cooling energy was 115 kW/m²/month.

- Optimization: Integration of pre-cooling and economizer systems reduced energy use by 26 kW/m²/month.

4. Energy-Saving Strategies

4.1 Pre-Cooling Systems

- Principle: Use ambient air or waste heat to pre-cool intake air before refrigeration.

- Impact: Reduces compressor workload by 15–20% in moderate climates.

4.2 Economizer Integration

- Function: Recovers waste heat from the condenser for secondary processes (e.g., water heating).

- Result: Achieved 72 kW/m²/month energy savings in the Rockhampton case study.

4.3 Smart Control Systems

- Variable Speed Drives (VSDs): Adjust compressor speed based on load demand.

- IoT Sensors: Monitor real-time parameters (temperature, pressure) for predictive maintenance.

5. Challenges and Future Directions

5.1 Limitations

- Ambient Temperature Dependency: Efficiency drops in high-temperature environments.

- Noise Pollution: Compressors and fans generate operational noise.

5.2 Innovations

- Hybrid Systems: Combine SACs with evaporative cooling for arid regions.

- AI-Driven Optimization: Machine learning models to predict load demands and adjust operations.

6. Conclusion

Screw air-cooled chillers are indispensable in modern industrial cooling systems. By integrating pre-cooling, economizers, and smart controls, their energy efficiency can be significantly enhanced. Future research should focus on hybrid designs and AI integration to address climate-specific challenges.

References

- Chowdhury, A. A., Rasul, M. G., & Khan, M. M. K. (2009). Modelling and analysis of air-cooled reciprocating chiller and demand energy savings using passive cooling. Applied Thermal Engineering, 29(9), 1845–1850.

- Sawant, P., Ho, E., & Pfafferott, J. (2020). Application and analysis of a model-based controller for cooling towers in compression chiller plants.