Performance, Design, and Sustainability of Water-Cooled Chillers in Modern Industrial and Commercial Applications

1. Introduction

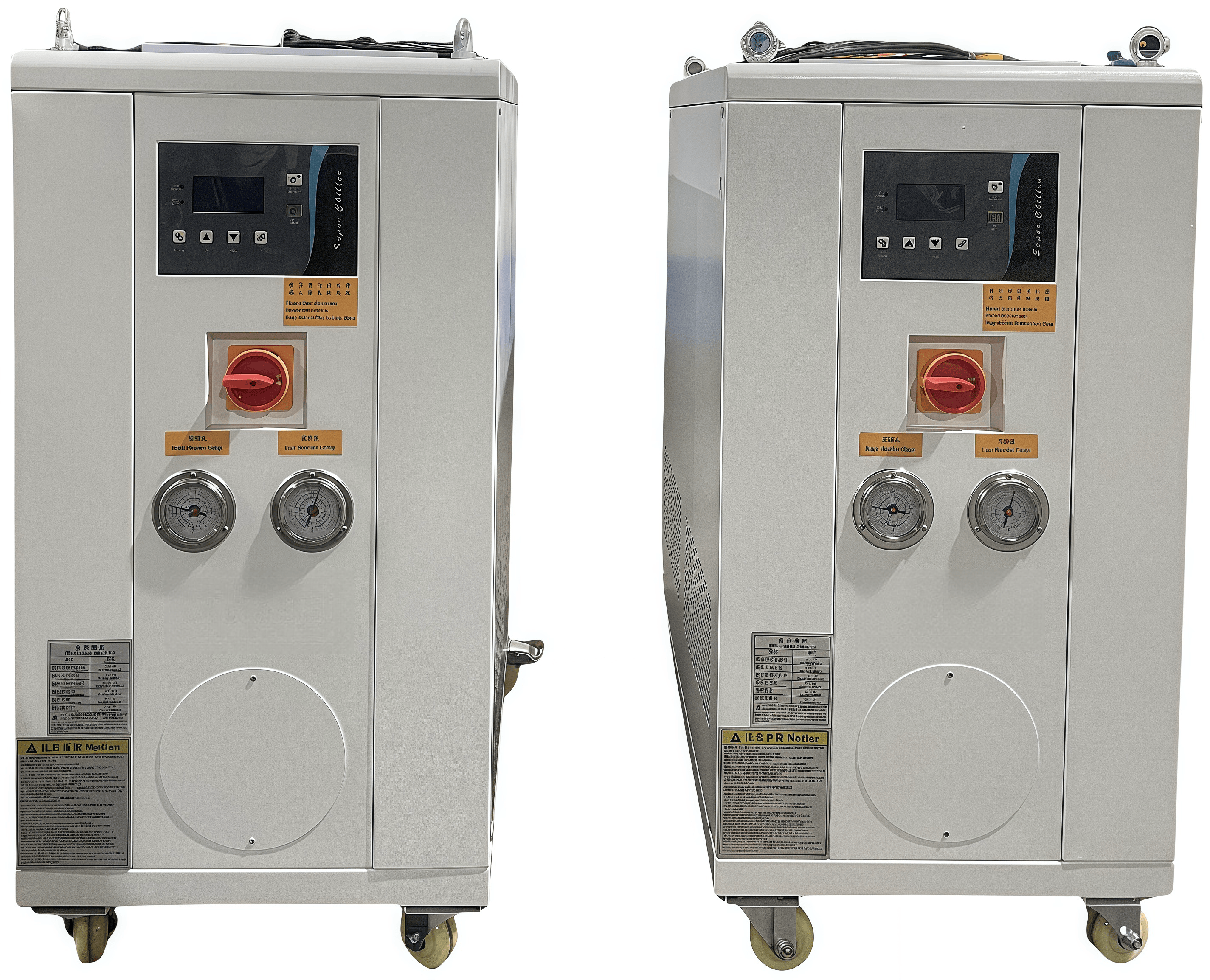

As global energy consumption in HVAC&R (Heating, Ventilation, Air Conditioning, and Refrigeration) systems continues to rise, the demand for high-efficiency, reliable, and environmentally responsible cooling technologies has intensified. Among available options, water-cooled chillers stand out for their ability to deliver large cooling capacities (typically 100 kW to several megawatts) with exceptional energy efficiency, especially in hot and humid climates where air-cooled systems suffer performance degradation [2][7].

Unlike air-cooled chillers that reject heat directly to ambient air via finned condensers, water-cooled units transfer waste heat to a recirculating water loop, which is then cooled by an external cooling tower [2]. This indirect heat rejection enables lower condensing temperatures (typically 35–40°C vs. 45–55°C for air-cooled), resulting in reduced compressor work and higher COP values [6].

This paper provides a technical and strategic overview of water-cooled chiller systems, with focus on design, performance sensitivity to manufacturing tolerances, and evolving market trends—particularly in China, which accounts for over 25% of global production and is projected to reach a market size of $12.5 billion by 2030 [9].

2. Working Principle and System Architecture

Water-cooled chillers operate on the vapor-compression refrigeration cycle, comprising four essential components:

- Compressor: Drives refrigerant circulation. Common types include reciprocating, screw, and centrifugal compressors. Screw compressors dominate mid-to-large capacity applications due to their balance of efficiency, reliability, and part-load performance [5][6].

- Shell-and-Tube Condenser: Transfers heat from high-pressure refrigerant vapor to cooling water. Constructed with copper or stainless-steel tubes and steel shells, often featuring enhanced inner surfaces (e.g., rifled tubes) to improve heat transfer [3][8].

- Evaporator: Absorbs heat from chilled water (typically 7/12°C supply/return). Can be dry-expansion or flooded-type; the latter offers higher efficiency but requires precise oil management [8].

- Expansion Device: Usually a thermostatic expansion valve (TXV) or electronic expansion valve (EEV) for precise refrigerant metering under variable loads [8].

The cycle begins when the compressor pressurizes low-pressure refrigerant vapor into a high-temperature, high-pressure gas. In the condenser, this gas releases heat to the cooling water and condenses into liquid. After expansion, the low-pressure liquid absorbs heat in the evaporator, cooling the process water before returning to the compressor [2][7].

3. Performance Parameters and Tolerance Sensitivity

Key performance indicators include:

- Cooling Capacity (kW or RT): Ranges from 30 kW (small modular units) to over 3,000 kW (centrifugal systems).

- COP (Coefficient of Performance): Typically 4.5–6.5 for modern screw or centrifugal chillers under nominal conditions (evaporator: 7°C in/12°C out; condenser: 30°C in/35°C out).

- IPLV (Integrated Part Load Value): Reflects efficiency across variable loads. Dual-compressor screw chillers can achieve IPLV > 6.0 by operating one compressor at low load [5].

Critically, national standard tolerances (e.g., GB/T standards in China) significantly influence real-world performance. As noted in [1], allowable deviations in:

- Heat exchanger dimensions,

- Refrigerant charge,

- Compressor displacement, and

- Sensor calibration

can collectively reduce COP by 5–12% and increase noise or vibration if not tightly controlled. Therefore, strict quality assurance and factory testing are essential to ensure compliance and optimal operation.

4. Advanced Configurations: Dual-Compressor Screw Chillers

A notable innovation is the water-cooled dual-compressor screw chiller, which integrates two independent screw compressors within a single unit [5]. Benefits include:

- Redundancy: One compressor can maintain ~70% cooling capacity during maintenance or failure.

- Load Matching: Enables efficient operation across 25–100% load range, avoiding “over-sizing” inefficiencies.

- Precision Control: Achieves ±0.5°C temperature stability—critical for pharmaceutical and semiconductor processes.

- Modular Maintenance: Compressors can be serviced without full system shutdown.

Such systems are increasingly deployed in hospitals, data centers, and district cooling plants across China, driven by reliability and energy-saving mandates under the national “dual carbon” strategy [5][9].

5. Refrigerants and Environmental Impact

Historically, R22 was widely used, but its phase-out under the Montreal Protocol has accelerated adoption of alternatives:

- R134a: Common in centrifugal and screw chillers; zero ODP but GWP = 1,430.

- R1234ze and R513A: Emerging low-GWP (<200) options compatible with existing designs.

- Natural Refrigerants (e.g., R717/ammonia): Used in industrial settings but require safety measures.

By 2030, China aims to reduce HFC consumption by 67.5% under the Kigali Amendment, pushing manufacturers toward next-generation refrigerants and oil-free magnetic bearing compressors [9].

6. Market Outlook: China’s Leadership and Growth Drivers

China is the world’s largest producer and consumer of water-cooled chillers. Key trends include:

- Market Size: Expected to grow from 12.5B (2030) at a CAGR of ~8.9% [9].

- Key Sectors: Data centers (fastest-growing), pharmaceuticals, chemical processing, and commercial real estate [4][9].

- Policy Support: Incentives for high-efficiency equipment under green building codes (e.g., GB 50189) and carbon trading schemes.

- Technological Shifts: Integration of IoT-based remote monitoring, AI-driven predictive maintenance, and variable frequency drives (VFDs) to optimize part-load efficiency [5][9].

The Asia-Pacific region, led by China, accounts for over 40% of global water-cooled chiller demand, driven by urbanization and industrial upgrading [4].

7. Energy-Saving and Operational Best Practices

To maximize lifecycle performance, operators should:

- Maintain cooling tower efficiency (clean fill, proper water treatment).

- Clean condenser tubes annually to prevent fouling (a 0.5 mm scale layer can increase energy use by 10%).

- Implement chilled water reset strategies based on ambient conditions.

- Use smart controls for compressor staging and pump speed modulation.

- Conduct regular refrigerant leak checks to preserve efficiency and comply with environmental regulations.

8. Conclusion

Water-cooled chillers remain the gold standard for high-capacity, high-efficiency cooling in modern infrastructure. Their superior thermodynamic performance, coupled with innovations in compressor design, refrigerant technology, and intelligent control, positions them as critical enablers of sustainable industrial and commercial development—particularly in China’s rapidly evolving low-carbon economy. Future advancements will focus on further reducing GWP, enhancing part-load efficiency, and integrating with smart grid and building energy management systems to support global climate goals.

-

Posted in

Industrial chiller