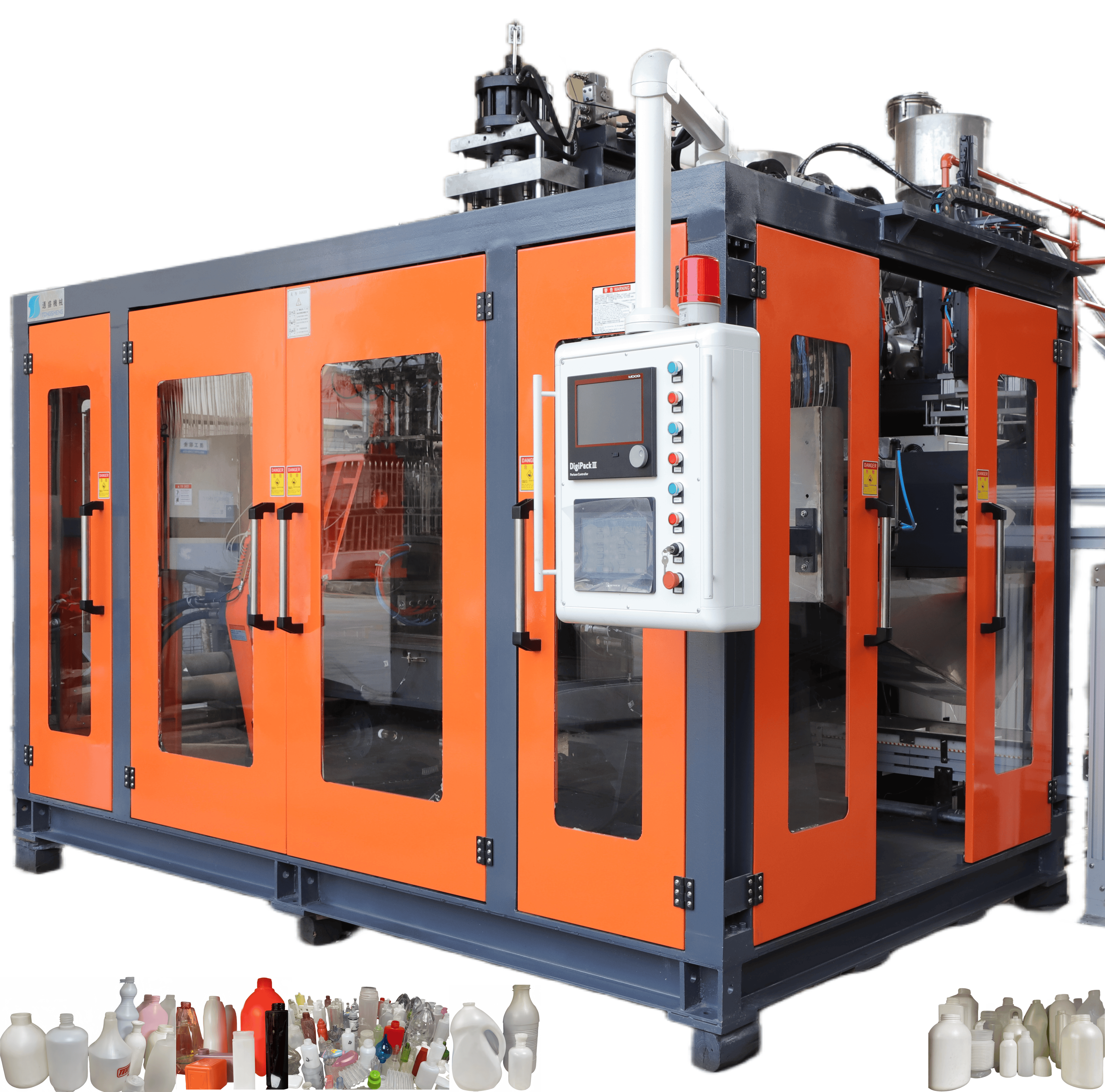

Hollow extrusion blow molding machine

1. Introduction

The global demand for lightweight, durable, and cost-effective plastic containers has propelled extrusion blow molding (EBM) to the forefront of polymer processing technologies. Unlike injection or injection-stretch blow molding, EBM excels in producing large, seamless, and complex-shaped hollow parts—such as fuel tanks, chemical drums, toolboxes, and milk jugs—using materials like HDPE, PP, PVC, and PET [2][8][9].

An extrusion blow molding machine (also termed a hollow extrusion blow molding machine) operates by extruding a molten tubular parison, capturing it between two mold halves, and inflating it with compressed air to conform to the mold cavity. Its simplicity, scalability, and low residual stress in final products make it ideal for mass production across packaging, automotive, and industrial sectors [1][5].

This paper explores the technological evolution of EBM machines, with a focus on precision control, energy conservation, and industrial digitization, particularly within the context of China’s rapidly advancing manufacturing ecosystem.

2. Machine Architecture and Working Principle

A typical EBM machine comprises the following subsystems [1][3][10]:

- Extruder: A single-screw or twin-screw unit that melts and homogenizes thermoplastic pellets (e.g., HDPE). The screw barrel is often made of 38CrMoAlA alloy steel, nitrided for wear and corrosion resistance [3].

- Die Head (Parison Head): Shapes the molten polymer into a tubular parison. Types include side-fed, center-fed, and accumulator-head designs—critical for large-volume containers to minimize parison sag [3][8].

- Clamping Unit: Hydraulic or servo-electric system that closes the mold halves with high force (typically 50–500 tons) and ensures precise alignment.

- Blowing System: Delivers compressed air (0.2–1.0 MPa) through a needle valve to inflate the parison. Pre-blowing is often used to prevent wall adhesion before final inflation [1].

- Cooling & Ejection: Mold cooling channels circulate water to solidify the part; robotic arms or pneumatic ejectors remove the finished product.

- Control System: Modern units employ PLC or IPC-based controllers with HMI interfaces for real-time monitoring and parameter adjustment [6].

The process sequence includes:

(1) Parison extrusion → (2) Mold closure and parison cutoff → (3) Blow inflation → (4) Cooling → (5) Mold opening and part ejection → (6) Trimming of flash [1][8].

3. Wall Thickness Control: From Manual to Intelligent Systems

Uniform wall thickness is critical for product strength, material economy, and aesthetics. Early EBM machines used two-stage hydraulic control—allowing only “thick” or “thin” zones [9]. Today’s advanced systems feature:

- Multi-point servo-controlled die heads (20–128 control points) that dynamically adjust the gap between mandrel and die ring during parison extrusion [3][6].

- Fuzzy-PID hybrid algorithms that compensate for system lag and nonlinearity, reducing overshoot and improving response time [6].

- Real-time monitoring of melt pressure, temperature, and parison diameter via sensors integrated into the IPC control platform [6].

Studies show that precise wall control can reduce raw material usage by 8–15% while enhancing impact resistance—particularly vital for chemical containers and automotive fuel tanks [9].

4. Energy-Saving Technologies

Given that plastic machinery accounts for a significant share of industrial electricity consumption in China, energy efficiency has become a strategic priority [1][5]. Two key innovations include:

- Variable Frequency Drives (VFDs): Adjust motor speed to match real-time load demands (e.g., 30 Hz instead of fixed 50 Hz), cutting motor energy waste by 20–40% [1][3].

-

Electromagnetic Heating: Replaces traditional resistance heaters with induction coils that directly heat the barrel. Benefits include:

- 30–70% higher thermal efficiency,

- Faster heating (25% reduction in startup time),

- Reduced ambient heat loss due to integrated insulation [3].

Companies like Shenzhen Guozhao Energy Technology have commercialized integrated VFD + electromagnetic systems (e.g., GZS series), achieving >35% total energy savings in dual-station EBM machines [1].

5. Market Landscape: China’s Leadership and Growth Drivers

China dominates global EBM equipment production and application. Key insights from 2025 data [5][7]:

- Market Size: Estimated at RMB 18 billion ($2.5B) in 2025, up from RMB 11.5 billion in 2020 (CAGR ≈ 13%) [5].

- Production Volume: ~48,000 units/year by 2025, led by manufacturers in Guangdong, Zhejiang, and Jiangsu [5][7].

-

Product Segmentation:

- Single-layer machines: ~65% market share (cost-effective for basic containers).

- Multi-layer co-extrusion machines: Growing rapidly (35% share) for barrier packaging (e.g., fuel tanks, edible oil bottles) [5].

-

Key Applications:

- Packaging (45%): beverage bottles, detergent containers.

- Automotive (25%): fuel tanks, air ducts, seat backs.

- Home appliances (20%): refrigerator liners, washing machine drums [5].

Government policies—such as “Made in China 2025” and “Dual Carbon” targets—are accelerating adoption of smart, energy-efficient EBM systems with IoT connectivity and predictive maintenance [5][7].

6. Future Trends

The next generation of EBM machines will likely feature:

- Full-electric servo drives replacing hydraulic systems for cleaner, quieter, and more precise operation.

- AI-powered process optimization using digital twins to simulate and adjust blow pressure, cooling time, and parison shape in real time.

- Integration with recycling lines: Direct use of post-consumer recycled (PCR) HDPE with viscosity compensation algorithms.

- Modular and mobile designs for on-demand manufacturing in distributed supply chains.

Moreover, multi-layer co-extrusion with EVOH or PA barrier layers will expand into food and pharmaceutical packaging to meet shelf-life and safety requirements [8].

7. Conclusion

Extrusion blow molding remains a cornerstone of modern plastic manufacturing, balancing cost, versatility, and performance. Through innovations in wall thickness control, energy efficiency, and digital integration—particularly in China—the hollow extrusion blow molding machine continues to evolve from a mechanical workhorse into an intelligent, sustainable production node. As global demand for circular, low-carbon packaging grows, EBM technology will play an increasingly vital role in shaping the future of polymer processing.

-

Posted in

extrusion blow molding machine