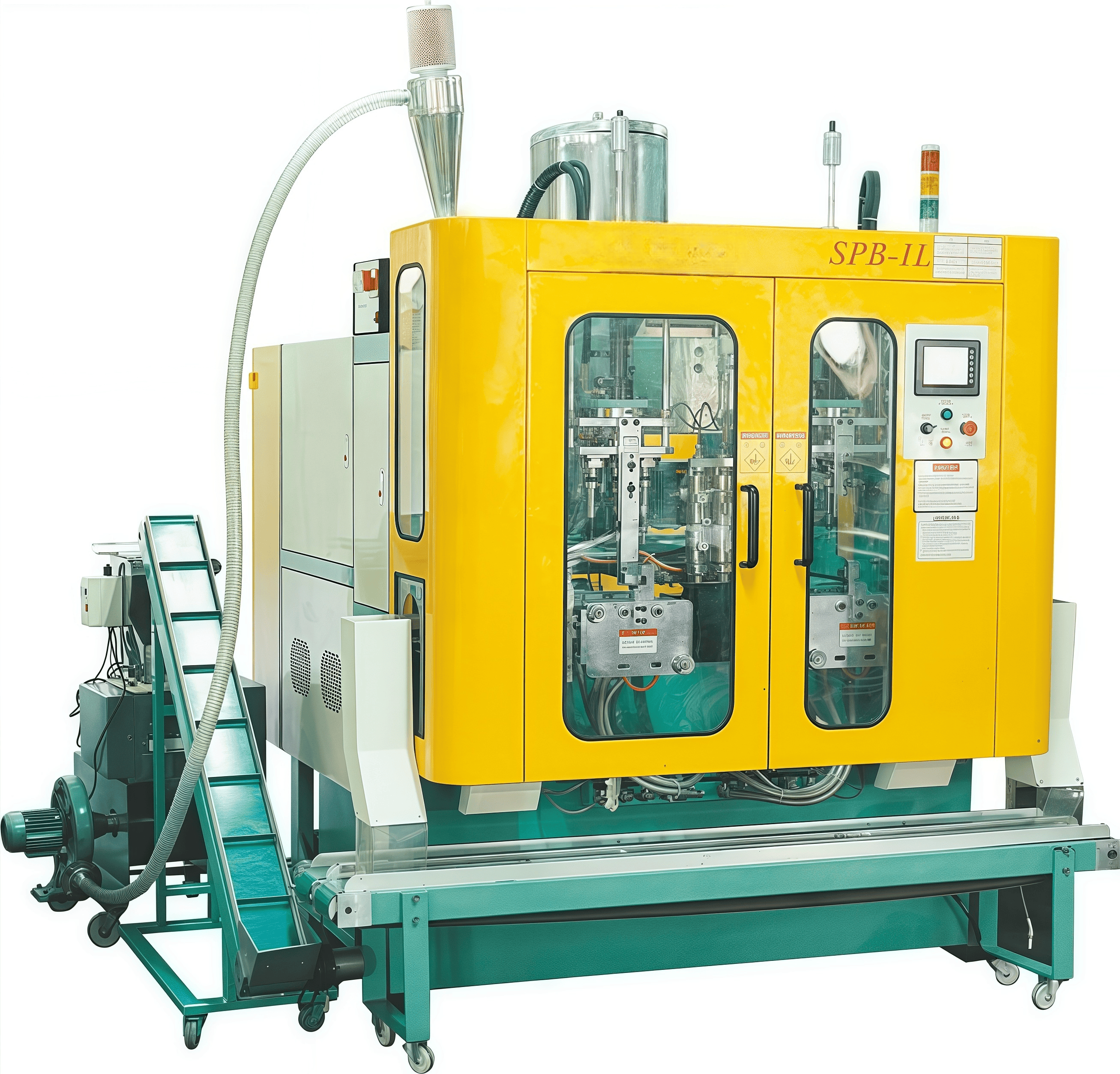

Design and Optimization of 1L Extrusion Blow Molding Machines for High-Efficiency Hollow Plastic Container Production

1. Introduction

Extrusion blow molding (EBM) is the most prevalent method for producing seamless, hollow thermoplastic containers in the 0.5–5L range. Among these, the 1-liter (1L) EBM machine has become a standard platform in packaging lines across automotive, household chemical, and pharmaceutical sectors due to its balance of speed, cost, and reliability [3][5][10].

Unlike injection blow molding—which offers higher dimensional accuracy but at greater tooling cost—EBM excels in low-to-mid volume production with minimal mold complexity and rapid changeover. In China, manufacturers such as Yijiu Machinery, LeShan Intelligent Equipment, and Tongda Mechanical have commercialized highly automated 1L machines capable of >1,200 pieces per hour with dual-station operation [3][12].

This paper examines the design, control logic, and performance optimization of modern 1L EBM machines, with emphasis on energy efficiency, product consistency, and adaptability to recycled HDPE feedstock.

2. Machine Configuration and Core Components

A typical 1L extrusion blow molding machine (e.g., YJH90-12LⅡ) features the following subsystems [3]:

| Component | Specification |

|---|---|

| Screw Diameter | 90 mm |

| L/D Ratio | 25 |

| Screw Motor Power | 37 kW |

| Extrusion Rate | 140 kg/h (HDPE) |

| Die Head Type | Continuous central-feed |

| Heating Zones | 4 (barrel) + 4 (die head) |

| Clamping Force | 120 kN |

| Mold Stroke | 280–750 mm |

| Blow Pressure | 0.6 MPa |

| Cooling Water Flow | 60 L/min |

| Cycle Time | ≤25 s |

| Output Capacity | 600 pcs/h per station × 2 = 1,200 pcs/h |

The machine operates on a dual-station principle: while one mold cools the part, the second performs extrusion, clamping, blowing, and ejection—effectively eliminating idle time and doubling throughput compared to single-station units [2][3].

3. Wall Thickness Control and Product Quality

Uniform wall distribution is critical for 1L containers to pass drop tests and meet regulatory standards (e.g., UN packaging for chemicals). Modern 1L machines employ:

- Servo-controlled mandrel positioning: Adjusts the die gap in real time during parison extrusion, enabling up to 32 control points along the parison length [5].

- Pre-blow function: A low-pressure air pulse prevents parison wall adhesion before main inflation [2].

- Infrared positioning system: Aligns the parison with the mold cavity within ±0.5 mm, minimizing flash and material waste [10].

These features allow wall thickness variation to be controlled within ±0.15 mm, reducing raw material usage by 8–12% without compromising structural integrity [5].

4. Energy Efficiency and Sustainability

Plastic processing accounts for ~5% of China’s industrial electricity consumption. To address this, 1L EBM machines now integrate two key energy-saving technologies:

4.1 Variable Frequency Drives (VFDs)

Traditional hydraulic systems run oil pumps at fixed speed (50 Hz), wasting energy via overflow valves. VFDs modulate motor speed based on real-time pressure demand. According to pump affinity laws:

A reduction from 50 Hz to 35 Hz cuts power consumption by ~65%. Field data from Shenzhen Guozhao Energy show 25–65% energy savings after VFD retrofitting [2].

4.2 Electromagnetic Heating

Replacing resistive heaters with induction coils directly heats the barrel, offering:

- 30–70% higher thermal efficiency,

- 25% faster warm-up,

- Reduced ambient heat loss due to integrated insulation [5].

For a 1L machine operating 20 hours/day, these measures save 8,000–12,000 kWh/year, supporting China’s carbon peaking goals [2][5].

5. Industrial Applications and Market Context

The 1L EBM machine dominates production of:

- Automotive: Engine oil bottles, brake fluid reservoirs,

- Household: Detergent, shampoo, and bleach containers,

- Agriculture: Pesticide and fertilizer bottles,

- Medical: Reagent and sample storage vials.

In China, over 48,000 EBM machines were produced in 2024, with small-capacity (<5L) units accounting for ~60% of total output [7]. Leading manufacturers like LeShan and Tongda offer modular 1L platforms compatible with recycled HDPE (rHDPE), enabling circular economy integration [10][12].

Recent patents (e.g., CN220331944U) highlight innovations such as rotary multi-mold heads, allowing rapid product changeover without manual die replacement—boosting flexibility for multi-SKU production lines [1].

6. Future Trends

The next generation of 1L EBM machines will likely feature:

- Full-electric servo clamping (replacing hydraulics for cleaner operation),

- IoT-enabled remote monitoring with cloud-based diagnostics,

- AI-driven process optimization using digital twins,

- Multi-layer co-extrusion for barrier packaging (e.g., EVOH/HDPE for fuel additives).

Moreover, compatibility with post-consumer recycled (PCR) resins will become standard, driven by EU and Chinese extended producer responsibility (EPR) regulations.

7. Conclusion

The 1-liter extrusion blow molding machine exemplifies the convergence of mechanical precision, intelligent control, and sustainable engineering. Through dual-station design, advanced wall thickness regulation, and energy-efficient technologies, it delivers high-speed, low-waste production of essential packaging components. As global demand for lightweight, recyclable containers grows, the 1L EBM platform will remain indispensable—particularly in China, where innovation and scale continue to drive the industry forward.

-

Posted in

extrusion blow molding machine