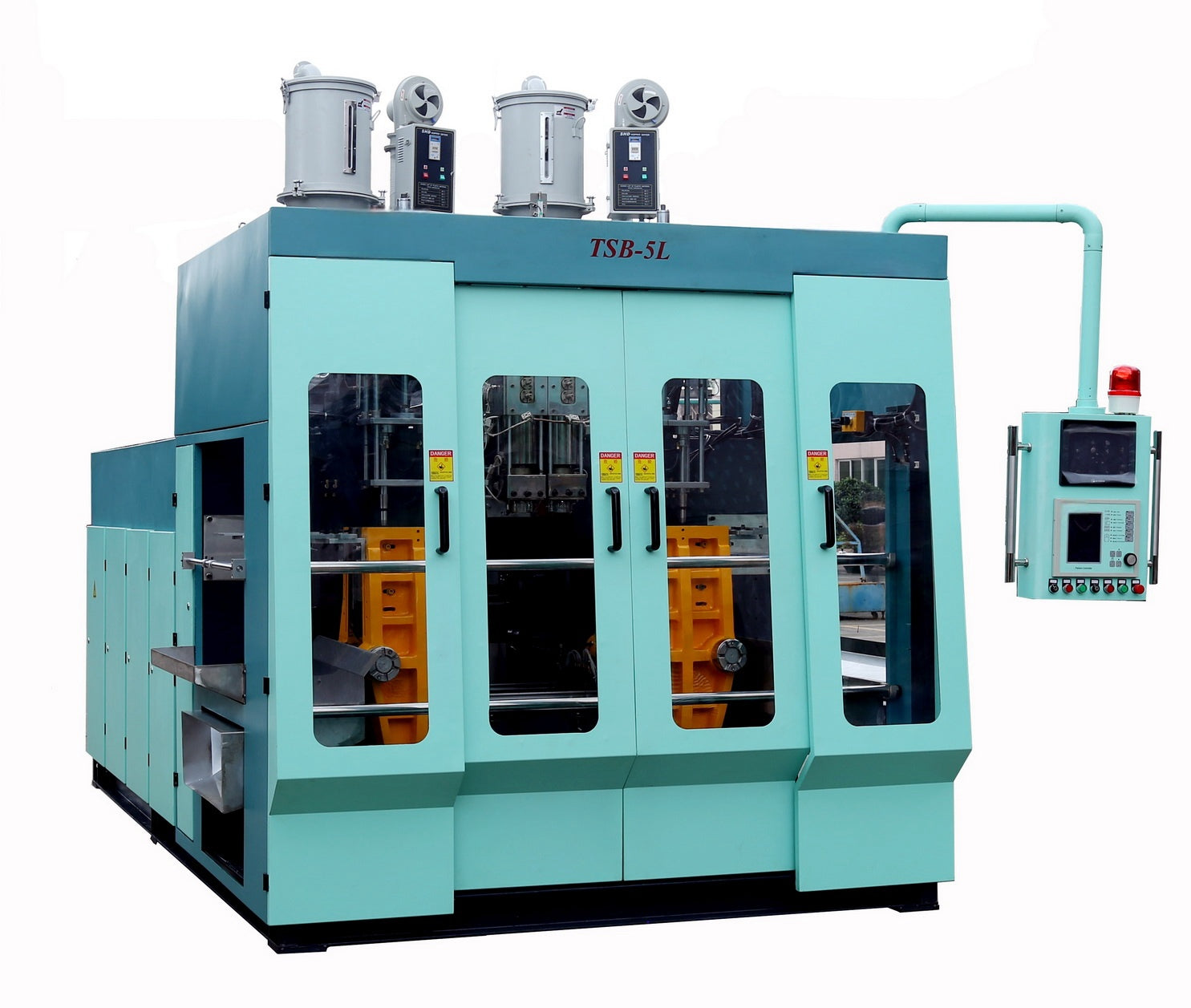

The 5L Extrusion Blow Molding Machine: Engineering Precision for Medium-Capacity Hollow Plastic Containers

1. Introduction Extrusion Blow Molding (EBM) is a dominant and rapidly evolving plastic processing technology responsible for manufacturing approximately 75% of all blow-molded products, ranging from small bottles to large industrial tanks. The 5L capacity machine occupies a vital niche in this spectrum, designed for the efficient, continuous production of containers that are ubiquitous in daily life and industry, such as detergent bottles, edible oil jugs, and chemical carriers. Unlike injection blow molding, which is better suited for smaller, high-precision items, EBM excels in producing larger, often more complex hollow forms at a lower tooling cost. This paper focuses on the specific design, operation, and technological advancements of the 5L EBM machine, highlighting how its engineering addresses the challenges of material distribution, energy consumption, and production speed to meet the demands of modern manufacturing.

2. Machine Architecture and Core Components A 5L EBM machine is an integrated system comprising several key subsystems that work in precise sequence.

-

2.1. Extruder Unit: The process begins with the extruder, typically a single-screw machine. Raw plastic pellets (commonly High-Density Polyethylene - HDPE, but also PVC, PP, or PET) are fed into the hopper. Inside the barrel, a rotating screw conveys, compresses, and melts the material through a combination of mechanical shear and external heating. The screw and barrel are often made from hardened, corrosion-resistant alloys like 38CrMoAlA, which are nitrided for enhanced durability and wear resistance. The molten plastic is then forced towards the die head.

-

2.2. Parison Die Head: This is arguably the most critical component for product quality. The molten plastic exits the extruder through the die head, forming a continuous, tubular parison. For a 5L machine, the die head must be precisely engineered to produce a parison with a diameter and wall thickness suitable for the final 5L mold cavity. Die heads can be side-fed or center-fed, with the latter often preferred for better symmetry in larger containers. The die head's design directly influences the initial parison thickness profile.

-

2.3. Clamping and Mold Unit: Once a sufficient length of parison is extruded, a two-part mold (often made of aluminum or steel) closes rapidly around it, pinching off the bottom and sealing the top (where the blow pin will enter). The mold halves are mounted on a robust clamping unit that provides the high force necessary to hold the mold closed against the internal air pressure during blowing. The mold cavity is precisely machined to the negative shape of the final product and is equipped with cooling channels.

-

2.4. Blow Pin and Air System: Immediately after mold closure, a blow pin descends into the neck of the parison. High-pressure, compressed air (typically 0.5-1.0 MPa) is injected through the pin, inflating the hot, plastic parison until it conforms perfectly to the contours of the cooled mold cavity. The air pressure and timing are carefully controlled to ensure complete filling without over-stretching the material.

-

2.5. Take-Out and Trimming Unit: After a brief cooling period (usually a few seconds to tens of seconds, depending on part thickness), the mold opens, and an automated take-out system removes the formed container. A separate trimming station, often integrated into the machine cycle, cuts away the excess plastic (flash) from the top (neck) and bottom (pinch-off) of the container, yielding the finished product.

3. The Critical Role of Parison Wall Thickness Control For a 5L container, achieving uniform wall thickness is not just about aesthetics; it is fundamental to structural strength, material economy, and product performance. A poorly controlled parison leads to thin spots that are prone to rupture and thick spots that waste material and increase cooling time.

-

3.1. Evolution of Control Technology: Early EBM machines had rudimentary control, perhaps offering only two fixed thickness settings (thick/thin) via hydraulic adjustment of the die gap. This was insufficient for complex 5L shapes with varying stress requirements.

-

3.2. Modern Multi-Point Control Systems: Contemporary 5L machines are equipped with sophisticated, computer-controlled parison programming systems. These systems use servo-hydraulic or all-electric servo actuators to dynamically adjust the gap between the die core and die bushing as the parison is being extruded.

- Multi-Zone Programming: The parison is divided into numerous axial zones (commonly 20-30 points, with advanced systems offering up to 128 points). For each zone, the operator can program a specific die gap, dictating the local wall thickness of the parison.

- Precision and Benefits: This allows for strategic material placement. For instance, more material can be programmed for the base and handle areas of a 5L jug, which bear more stress, while less material is used for the sidewalls. Modern all-electric systems can achieve thickness control accuracies within ±0.05mm. The benefits are substantial: up to 15-25% reduction in material usage, improved impact resistance (as demonstrated by drop tests), shorter cycle times due to faster cooling of thinner sections, and overall higher product quality and consistency.

4. Operational Workflow and Cycle The operation of a 5L EBM machine is a continuous, cyclical process:

- Extrusion: The extruder continuously produces a molten parison.

- Mold Closure & Parison Sealing: When the parison reaches the required length, the mold closes, pinching it at the bottom.

- Blow Molding: The blow pin enters, and compressed air inflates the parison against the mold walls.

- Cooling & Solidification: The mold's cooling system rapidly extracts heat, solidifying the plastic into its final shape.

- Mold Opening & Ejection: The mold opens, and the formed container is ejected.

- Trimming: Excess flash is automatically trimmed.

- Cycle Repeat: The process repeats immediately for the next container. Cycle times for a 5L container typically range from 10 to 30 seconds, enabling high production rates.

5. Energy Efficiency and Technological Advancements Modern 5L EBM machines incorporate various technologies to reduce their environmental footprint and operating costs.

-

5.1. Drive System Efficiency:

- Variable Frequency Drives (VFDs): Widely adopted for the main extruder drive motor. A VFD allows the motor speed (and thus output) to be precisely matched to the production rate, eliminating energy waste from running at full speed when not needed. This can yield energy savings of 30-50% on the drive system.

-

5.2. Heating System Efficiency:

- Electromagnetic Induction Heaters: Replacing traditional resistance heaters on the extruder barrel, these heaters are significantly more efficient (30-70% energy savings). They work by inducing eddy currents directly within the metal barrel, providing faster, more responsive, and more uniform heating with less radiant heat loss due to integrated insulation.

- 5.3. Control System Intelligence: Advanced microprocessor-based controllers manage the entire process, optimizing parameters for minimal energy use while maintaining quality. They also provide diagnostics and data logging for predictive maintenance.

6. Primary Applications and Market Significance The 5L EBM machine is indispensable for producing a vast array of containers critical to various sectors:

- 6.1. Household and Industrial Chemicals: Detergent bottles, bleach containers, fabric softener jugs, and industrial solvent carriers. HDPE is the dominant material due to its excellent chemical resistance.

- 6.2. Food and Beverage Packaging: Edible oil containers, large juice or syrup bottles, vinegar jugs, and food-grade storage containers. Material choice is critical for food safety compliance.

- 6.3. Automotive and Industrial Parts: While less common for 5L sizes, EBM can produce larger automotive components like fuel tanks (though often larger machines are used) or industrial containers for lubricants and fluids.

- 6.4. Other Consumer Goods: Large water cooler bottles, sports drink containers, and bulk cosmetic product packaging.

The ability to produce these containers at high speed, with low tooling costs compared to injection molding, and with excellent material efficiency (thanks to wall thickness control) makes the 5L EBM machine a cornerstone of the global packaging industry.

7. Challenges and Future Outlook Despite its maturity, the technology continues to evolve.

-

7.1. Current Challenges:

- Material Limitations: While versatile, EBM is generally limited to thermoplastics and struggles with very high-viscosity materials or those requiring extremely high dimensional precision.

- Flash Waste: Although recyclable, the trimming process generates flash that must be reground and fed back into the extruder, adding a step to the process.

-

7.2. Future Trends:

- Increased Automation and IIoT: Greater integration with factory automation systems for seamless material handling, quality inspection, and real-time production data analytics via the Industrial Internet of Things (IIoT).

- All-Electric Machines: The shift from hydraulic to all-electric servo drives for mold clamping, parison control, and take-out systems will continue, offering even greater precision, energy savings, and a cleaner operating environment.

- Advanced Materials and Multi-Layer: Development of machines capable of handling new, sustainable bio-based resins and producing multi-layer containers (e.g., for enhanced barrier properties) for more demanding applications.

- AI-Driven Process Optimization: Implementation of artificial intelligence to dynamically adjust parison profiles and process parameters in real-time based on sensor feedback, further minimizing waste and maximizing quality.

8. Conclusion The 5L extrusion blow molding machine is a sophisticated and highly optimized piece of manufacturing equipment, perfectly calibrated for the mass production of essential medium-capacity plastic containers. Its success lies in the seamless integration of robust mechanical systems—the extruder, die head, clamping unit, and blow system—with intelligent electronic controls, most notably the multi-point parison wall thickness programmer. This technology transforms a simple tube of molten plastic into a structurally sound, material-efficient, and aesthetically pleasing container. The ongoing incorporation of energy-saving technologies like VFDs and electromagnetic heaters, coupled with the trend towards all-electric actuation and smart factory integration, ensures that the 5L EBM machine will remain a vital, efficient, and evolving technology at the heart of the global plastics packaging industry for years to come. Its role in balancing production speed, cost-effectiveness, and increasingly, environmental responsibility, is more critical than ever.

-

Posted in

extrusion blow molding machine