Design, Operation, and Industrial Applications of 1-Liter Extrusion Blow Molding Machines Abstract

1. Introduction

The global demand for lightweight, recyclable, and cost-efficient plastic containers has driven continuous innovation in blow molding technology. Containers of 1-liter capacity are among the most commonly produced items worldwide—used for bottled water, edible oils, shampoos, detergents, and pharmaceutical solutions. Extrusion blow molding, as opposed to injection or stretch blow molding, offers distinct advantages for this volume range: seamless construction, excellent chemical resistance, and compatibility with a wide range of thermoplastics, especially high-density polyethylene (HDPE) and polypropylene (PP).

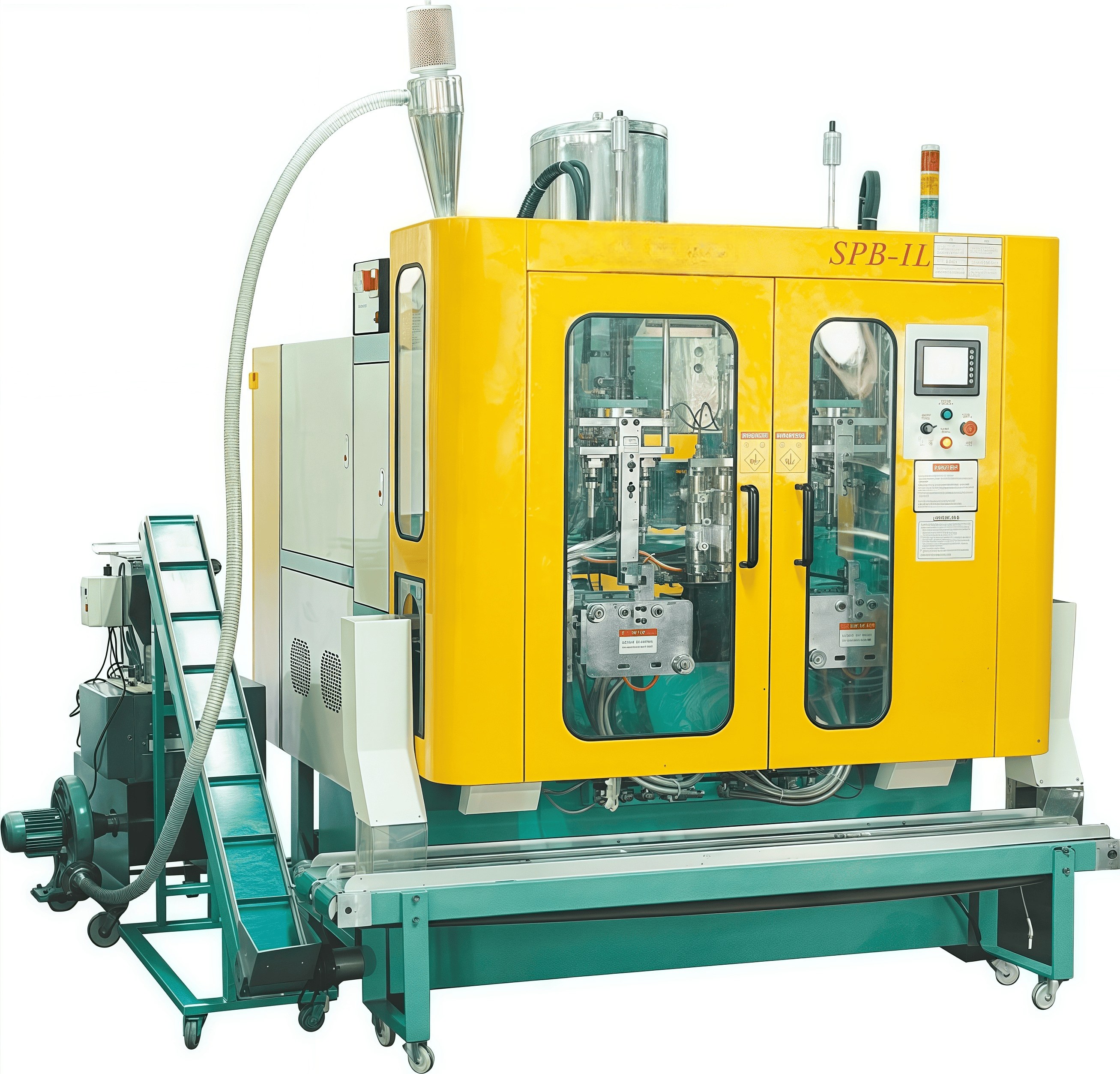

A 1L EBM machine is typically compact, energy-efficient, and designed for rapid cycling—making it ideal for small-to-medium enterprises and high-mix production environments.

2. Working Principle of Extrusion Blow Molding

As described in [3], the extrusion blow molding process involves the following key steps:

- Plastic Melting and Extrusion: Thermoplastic pellets (e.g., HDPE) are fed into a single-screw extruder, where they are melted and homogenized under heat and shear.

- Parison Formation: The molten plastic is extruded through an annular die to form a hollow tube called a parison.

- Mold Clamping: The parison is captured between two mold halves, which close rapidly under hydraulic or mechanical force.

- Blow Molding: Compressed air (typically 0.3–0.6 MPa) is injected into the parison, inflating it against the mold cavity to take its final shape.

- Cooling and Ejection: The molded part is cooled by internal air and external mold cooling channels, then ejected automatically.

This cycle repeats continuously, with modern 1L machines achieving cycle times as low as 3–5 seconds.

3. Machine Configuration for 1L Production

A typical 1L extrusion blow molding machine features the following specifications:

-

Extruder:

- Screw diameter: 45–65 mm

- L/D ratio: 20:1 to 25:1

- Motor power: 11–22 kW

- Heating zones: 3–4 (total power: 4–8 kW)

- Output: 40–80 kg/h (HDPE)

-

Mold System:

- Clamping force: 30–60 kN

- Mold opening stroke: 200–400 mm

- Template size: ~300 × 300 mm

- Single- or dual-station configuration

-

Die Head:

- Continuous or shuttle-type

- Optional parison programming for wall-thickness control

- Integrated with quick-change adapters for multi-size production (e.g., 0.5L–2L)

-

Control & Automation:

- PLC-based control (e.g., Siemens, Delta)

- Touchscreen HMI for parameter setting

- Auto-start/stop, fault diagnosis, and data logging

- Integration with conveyors and vision inspection systems

As noted in [2], modern lines often incorporate high-efficiency extruders, rapid screen changers, and screw-type plastic blowing heads to enhance melt stability and reduce downtime.

4. Material and Product Flexibility

1L EBM machines commonly process:

- HDPE: For milk bottles, detergent containers (excellent chemical resistance)

- PP: For hot-fill applications (e.g., edible oil, sauces)

- Recycled resins (rHDPE): Supporting circular economy goals

- Co-extruded layers: For oxygen barrier (e.g., in juice bottles)

The ability to produce handle-integrated bottles, grip zones, and precision neck finishes (e.g., PCO 1810 for water) adds functional value.

5. Advantages and Limitations

Advantages:

- Low initial investment compared to stretch blow molding

- No preform required—simpler material logistics

- Excellent for opaque or pigmented containers

- High production speed for standard shapes

- Easy mold changeovers for product variety

Limitations:

- Lower dimensional precision than injection blow molding

- Flash (excess plastic at parting lines) requires trimming

- Limited to thermoplastics with good melt strength

- Wall-thickness control less precise than in advanced stretch blow systems

6. Industrial Applications

1L blow-molded containers are ubiquitous in:

- Beverage: Bottled water, juice, sports drinks

- Food: Cooking oil, vinegar, syrup

- Personal Care: Shampoo, lotion, hand sanitizer

- Household: Liquid detergent, bleach, fabric softener

- Pharmaceutical: Oral liquid bottles, reagent containers

The trend toward lightweighting (e.g., <25g bottle weight for 1L water) has pushed machine manufacturers to improve parison control and cooling uniformity.

7. Emerging Trends

Recent innovations in 1L EBM technology include:

- All-electric or hybrid drives: Reducing energy consumption by 20–30% and eliminating hydraulic oil

- AI-assisted process control: Real-time adjustment of blow pressure and cooling based on vision feedback

- Modular platforms: One machine producing 0.3L–2L via quick die/mold swaps

- Sustainability integration: Compatibility with post-consumer recycled (PCR) content up to 100%

These developments align with global initiatives for green manufacturing and Industry 4.0.

8. Conclusion

The 1-liter extrusion blow molding machine remains a cornerstone of modern plastic packaging, offering an optimal blend of simplicity, speed, and versatility. While newer technologies like stretch blow molding dominate in premium beverage segments, EBM continues to thrive in cost-sensitive, high-volume applications. With ongoing advances in automation, energy efficiency, and material science, 1L EBM systems are well-positioned to meet the evolving demands of a sustainable and digitalized manufacturing future.