Performance, Design, and Sustainability of Water-Cooled Chillers in Modern Industrial and Commercial Applications

1. Introduction As global energy consumption in HVAC&R (Heating, Ventilation, Air Conditioning, and Refrigeration) systems continues to rise, the demand for high-efficiency, reliable, and environmentally responsible cooling technologies has intensified. Among available options, water-cooled chillers stand out for their ability to deliver large cooling capacities (typically 100 kW to several megawatts) with exceptional energy efficiency, especially in hot and humid climates where air-cooled systems suffer performance degradation [2][7]. Unlike air-cooled...

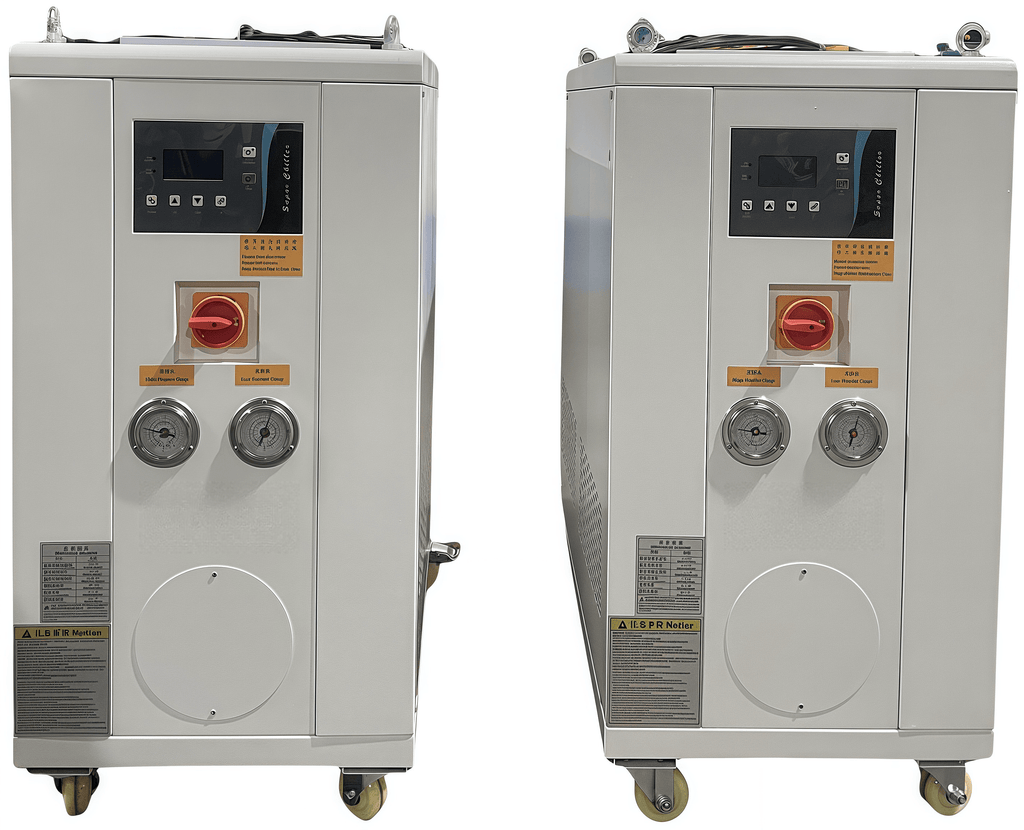

Advancements in Air-Cooled Chiller Technology: Design, Applications, and Sustainability in Modern Industrial Cooling

1. Introduction With global industrial energy consumption rising and water resources becoming increasingly constrained, the demand for efficient, low-maintenance, and environmentally responsible cooling solutions has intensified. Air-cooled chillers—also known as air-cooled industrial chillers or air-cooled box-type chillers—offer a compelling alternative to traditional water-cooled systems by eliminating the need for cooling towers, water treatment, and complex piping networks [2][5]. Widely deployed in plastics processing, laser equipment, data centers, pharmaceuticals, food &...

Advancements in Plastic Crushing Technology: Design, Applications, and Role in the Circular Economy Abstract

1. Introduction The proliferation of single-use and durable plastic products has led to mounting waste accumulation in landfills and oceans. Mechanical recycling remains the most economically viable and scalable solution for managing thermoplastic waste. At the heart of this process lies the plastic crusher, which reduces bulky plastic items—such as bottles, pipes, films, and automotive parts—into uniform granules or flakes suitable for washing, separation, and re-extrusion. Recent advancements in crusher...

Design and Industrial Application of 12-Liter Extrusion Blow Molding Machines Abstract

1. Introduction The demand for robust, chemically resistant, and cost-effective large-volume containers has driven continuous innovation in extrusion blow molding. The 12-liter format is widely adopted across automotive, agricultural, and chemical sectors due to its optimal balance between handling ergonomics, transport efficiency, and product protection. Unlike smaller containers produced via injection or stretch blow molding, 12L bottles require high melt strength, precise wall-thickness control, and integrated structural features such as...

Advanced 5-Liter Extrusion Blow Molding Machines: Multi-Material Flexibility, High-Throughput Design, and Industrial Packaging Applications

1. Introduction The 5-liter container format has become a global standard for products requiring robust, chemical-resistant, and user-friendly packaging. Unlike smaller bottles produced via stretch blow molding, 5L containers benefit from the seamless, stress-free construction of extrusion blow molding, which accommodates integrated handles, thick walls, and multi-layer barrier structures. With rising demand for automation, material efficiency, and recyclability, manufacturers have developed advanced EBM platforms capable of producing 5L bottles at...

Design and Application of 2.5-Liter Extrusion Blow Molding Machines in Modern Packaging Industry Abstract

1. Introduction As global demand for durable, lightweight, and recyclable plastic containers grows, the 2.5L format has emerged as a key standard in industrial and consumer packaging. It balances ergonomic handling, logistical efficiency, and product visibility—making it ideal for premium cooking oils, detergent concentrates, lubricants, and agrochemicals. Unlike injection or stretch blow molding, extrusion blow molding excels in producing seamless, stress-free containers with integrated handles and variable wall thickness, especially...

Advanced 1.8-Liter Extrusion Blow Molding Machines: Design, Multi-Layer Capability, and High-Speed Industrial Applications

1. Introduction The global packaging industry increasingly requires flexible, efficient, and sustainable production systems capable of handling diverse container volumes and material formulations. Among standardized sizes, the 1.8-liter (1800 mL) format has gained prominence for premium edible oils, cosmetic serums, household cleaners, and specialty chemical packaging. Unlike smaller bottles produced via injection stretch blow molding, 1.8L containers benefit from the seamless, stress-free construction of extrusion blow molding, which accommodates thicker...

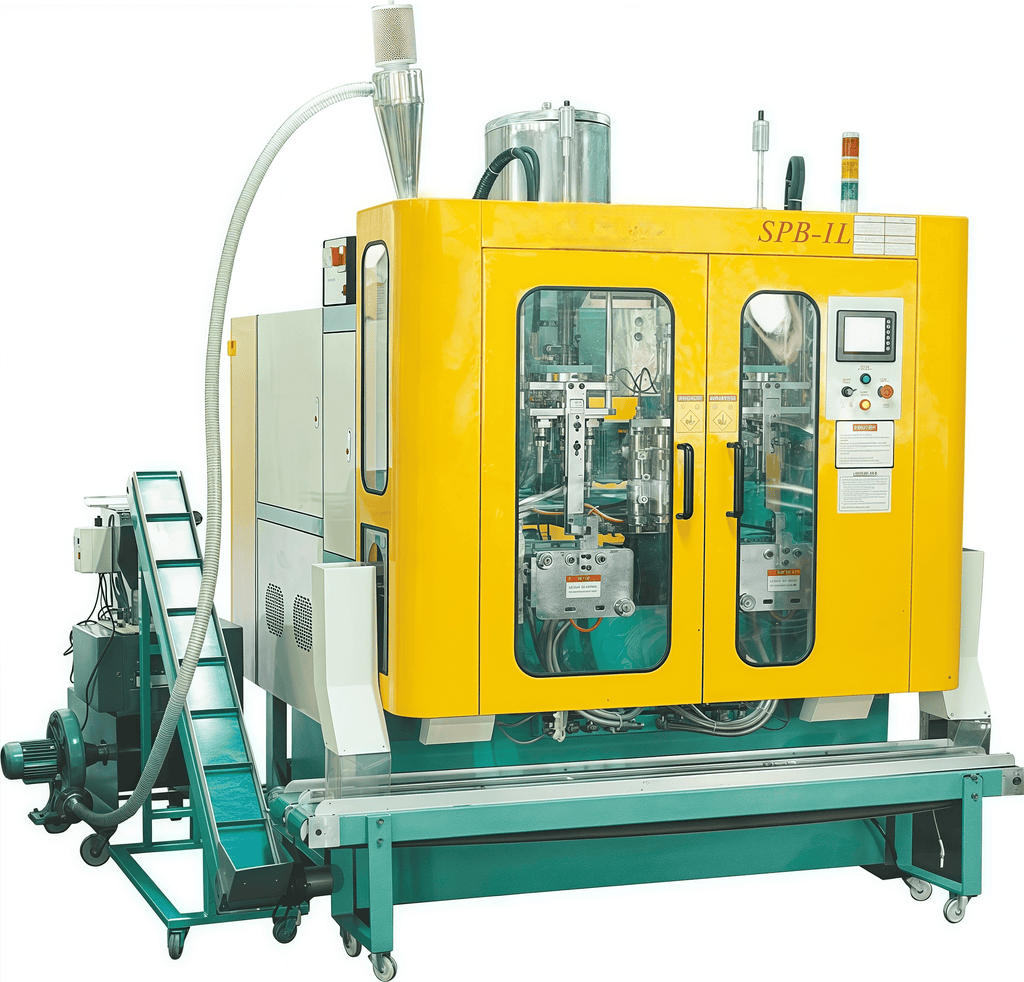

Design, Operation, and Industrial Applications of 1-Liter Extrusion Blow Molding Machines Abstract

1. Introduction The global demand for lightweight, recyclable, and cost-efficient plastic containers has driven continuous innovation in blow molding technology. Containers of 1-liter capacity are among the most commonly produced items worldwide—used for bottled water, edible oils, shampoos, detergents, and pharmaceutical solutions. Extrusion blow molding, as opposed to injection or stretch blow molding, offers distinct advantages for this volume range: seamless construction, excellent chemical resistance, and compatibility with a wide...