Design, Operation, and Energy Efficiency of Water-Cooled Chillers in HVAC Systems Abstract

1. Introduction

With the increasing demand for energy-efficient building systems, chillers play a vital role in providing cooling for large commercial, industrial, and institutional facilities. Among various chiller types, water-cooled chillers are widely preferred in applications where high cooling capacity and energy efficiency are required. Unlike air-cooled chillers, which reject heat directly to the ambient air, water-cooled chillers use a secondary water loop and cooling towers to dissipate heat, resulting in lower condensing temperatures and higher coefficient of performance (COP). This paper explores the design, operation, and energy performance of water-cooled chillers, emphasizing their role in sustainable building environments.

2. Working Principle of Water-Cooled Chillers

Water-cooled chillers operate on the vapor-compression refrigeration cycle, which consists of four main processes: compression, condensation, expansion, and evaporation.

- Compression: The refrigerant vapor is compressed by a compressor (typically centrifugal, screw, or scroll type), increasing its pressure and temperature.

- Condensation: The high-pressure, high-temperature refrigerant enters the condenser, where it is cooled by a water loop. Heat is transferred to the cooling water, which is then circulated to a cooling tower.

- Expansion: The high-pressure liquid refrigerant passes through an expansion valve, reducing its pressure and temperature.

- Evaporation: In the evaporator, the low-pressure refrigerant absorbs heat from the chilled water loop, cooling the water before it is distributed to air handling units or fan coil units.

The condenser cooling water is typically recirculated through a cooling tower, where heat is rejected to the atmosphere via evaporation.

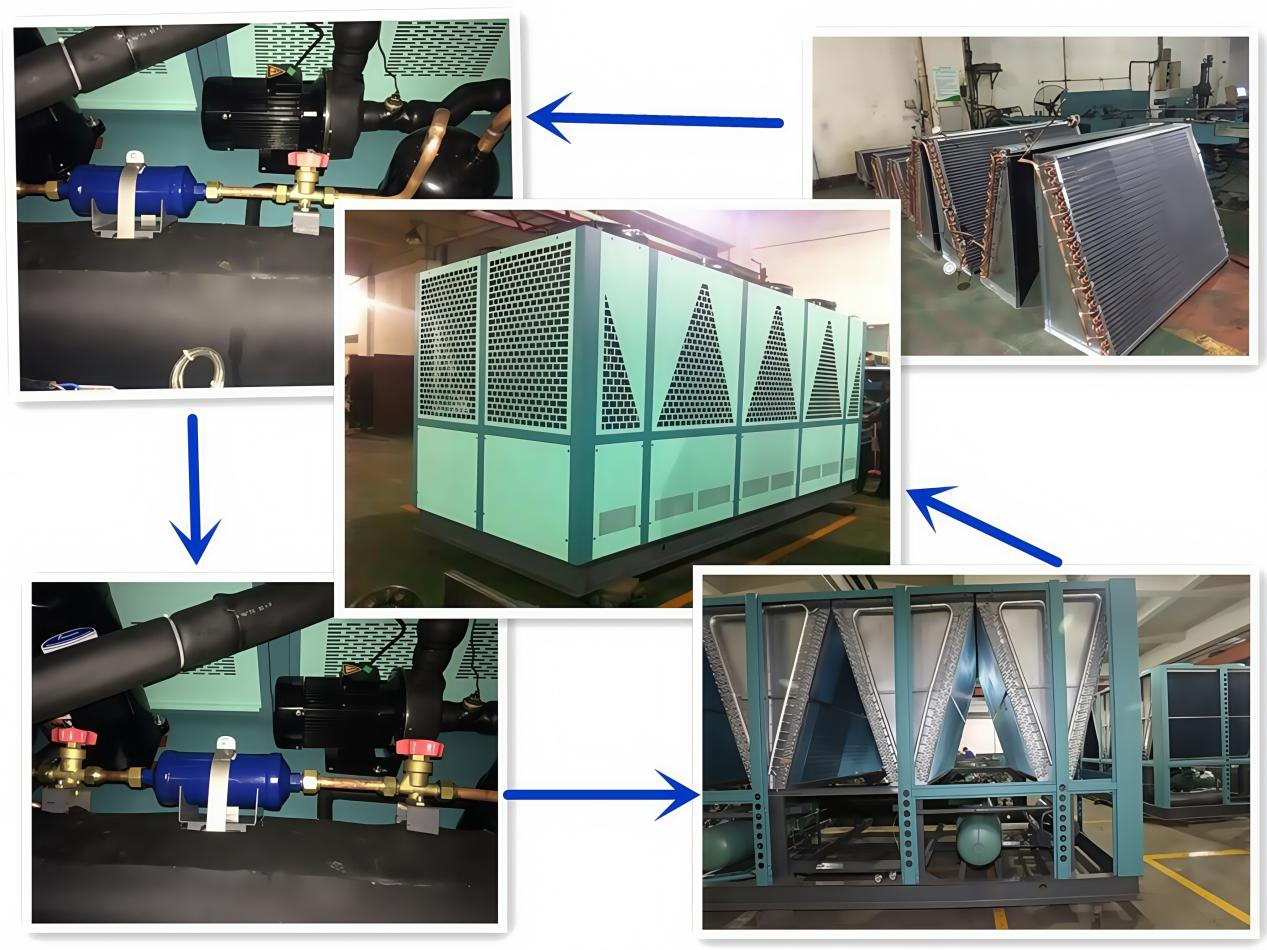

3. Key Components

A water-cooled chiller system consists of several critical components:

- Compressor: The heart of the system, responsible for circulating the refrigerant and increasing its pressure.

- Condenser: A shell-and-tube heat exchanger where refrigerant condenses by transferring heat to cooling water.

- Evaporator: Another heat exchanger where chilled water is cooled by the evaporation of refrigerant.

- Expansion Valve: Regulates refrigerant flow into the evaporator.

- Cooling Tower: Rejects heat from the condenser water to the atmosphere.

- Pumps and Piping: Circulate chilled water and condenser water throughout the system.

- Control System: Monitors and regulates temperature, pressure, and flow rates for optimal operation.

4. Performance Evaluation

The performance of water-cooled chillers is commonly evaluated using the following metrics:

- Coefficient of Performance (COP): Ratio of cooling output to electrical input. Water-cooled chillers typically achieve COP values between 5.0 and 7.0, significantly higher than air-cooled units.

- Energy Efficiency Ratio (EER) and Integrated Part Load Value (IPLV): Used to assess efficiency under varying load conditions.

- Chilled Water and Condenser Water Temperatures: Lower condensing temperatures due to effective heat rejection in cooling towers contribute to higher efficiency.

Modern chillers often meet or exceed ASHRAE Standard 90.1 efficiency requirements.

5. Applications

Water-cooled chillers are widely used in:

- High-rise commercial buildings

- Hospitals and laboratories

- Data centers

- Industrial processes requiring precise temperature control

- District cooling systems

Their ability to handle large cooling loads with high efficiency makes them ideal for facilities with continuous cooling demands.

6. Energy-Saving Technologies

Recent advancements have significantly improved the energy performance of water-cooled chillers:

- Variable Speed Drives (VSDs): Allow compressors to adjust speed based on load, reducing energy consumption during part-load operation.

- Advanced Control Algorithms: Optimize chiller sequencing, condenser water temperature, and cooling tower operation.

- High-Efficiency Heat Exchangers: Enhanced tube designs improve heat transfer and reduce fouling.

- Environmentally Friendly Refrigerants: Transition from R-134a and R-123 to low-GWP alternatives such as R-1233zd(E) and R-513A.

These technologies contribute to reduced operating costs and lower carbon emissions.

7. Challenges and Maintenance Considerations

Despite their advantages, water-cooled chillers require regular maintenance to ensure optimal performance. Issues such as scaling, fouling, and microbial growth in cooling towers can reduce heat transfer efficiency. Water treatment programs and routine inspections are essential. Additionally, the initial installation cost and space requirements for cooling towers are higher than for air-cooled systems.

8. Conclusion

Water-cooled chillers remain a cornerstone of efficient and reliable cooling in large-scale applications. Their superior energy efficiency, especially when integrated with modern control systems and energy-saving technologies, makes them a preferred choice for sustainable building design. Future developments are expected to focus on further reducing energy consumption, improving refrigerant sustainability, and enhancing smart integration with building energy management systems (BEMS). As global energy demands rise, optimizing water-cooled chiller systems will continue to play a crucial role in achieving energy conservation and environmental goals.

-

Đăng trong

Plastic crusher