PRODUCT DETAILS

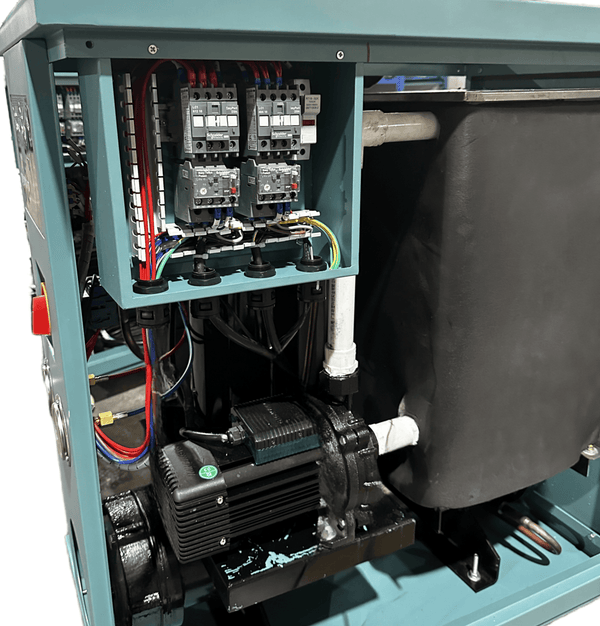

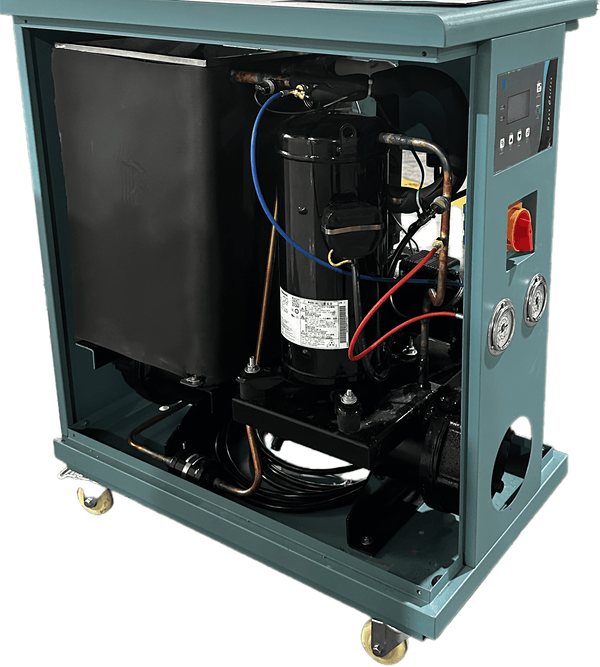

Water-cooled industrial chillers are pivotal for precise temperature control in manufacturing. Utilizing water as the condenser coolant—typically via a cooling tower—they offer superior efficiency and stability compared to air-cooled units, especially under high ambient temperatures or heavy loads. Their key components include a compressor, water-cooled condenser, expansion valve, and evaporator. Benefits include higher energy efficiency, lower operational noise, and extended equipment lifespan. They are essential in plastics, laser, chemical, and food processing industries, ensuring consistent product quality and process reliability by removing excess heat from machinery and processes.

Payment Delivery

Payment Delivery

- Contract Signing: A 30% deposit is required upon signing the contract.

- Payment Before Shipment: The remaining 70% is to be paid before shipment.

Production Cycle:

- Small Machines: Approximately 40 days.

- Large Machines: Approximately 70 days.